Published

by Rogers Corporation

Enclosure Institute

Welcome back to the Enclosure Institute™.

This two-part blog series explores a critical topic: why enclosure gaskets and seals fail. In part 1, we'll focus on material-related issues that can compromise sealing performance before the product is ever assembled including:

- Improper compression (too much or too little)

- Poor long-term elasticity

- Environmental exposure

- And more

Understanding these failure modes early in the design process can help you select the right materials, validate your choices, and avoid costly field issues down the line.

Here are some of the most common material and environmental causes of gasket failure and how to prevent them.

Overview: Why Seals Fail – Part 1: Materials and Environment

| Root Cause | Problem | Possible Solution(s) |

|---|---|---|

| Too Little or Too Much Compression | Incorrect compression can lead to gaps (under-compression) or material damage (over-compression). |

|

| Seal Collapses | Foam loses ability to rebound after compression (aka takes a set), leading to leaks. |

|

| Exposure to Extreme Temperatures | High heat or cold causes materials to crack, harden, or become brittle. |

|

| Repetitive Movement / Vibration / Cycling | Dynamic seals wear out due to constant motion and mechanical stress. |

|

| UV and Ozone Exposure | UV and ozone degrade gasket materials over time. |

|

| Chemical Degradation | Incompatible chemicals cause swelling, cracking, or material breakdown. |

|

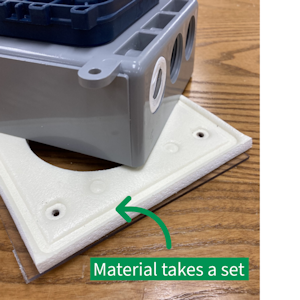

1. Too Little or Too Much Compression

Problem:

Incorrect compression—whether too little or too much—can lead to seal failure, material degradation, or leakage. Insufficient compression may leave gaps, while excessive compression can deform the material, reducing its effectiveness over time.

Possible Solutions:

- As general guidance, we recommend a compression range of 30%-50% for optimal sealing performance. Of course, this can vary based on material and application requirements.

- Conduct compression force testing under anticipated environmental conditions to validate the reliability of the seal.

- Work with Rogers and Marian to pinpoint the optimal compression for your application.

Image property of Rogers Corporation

Over compressed gasket resulting in material stretch

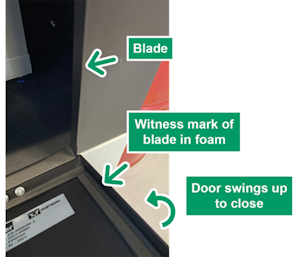

Image property of Rogers Corporation

Over compressed gasket resulting in mark of blade in foam

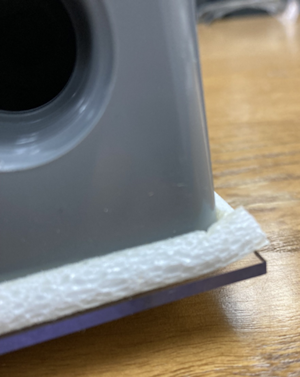

Image property of Marian Inc

2. The Seal Collapses (Poor Compression Set Resistance of the Gasket Material)

Problem:

This is one of the most common causes of gasket failure over time. Even if a seal performs well when initially installed, it can gradually lose its ability to return to its original shape after repeated compression—leading to permanent deformation known as compression set. When this happens, the seal becomes ineffective, allowing air, water, or contaminants to pass through. For example, an outdoor enclosure gasket may flatten over time, eventually allowing rain to leak inside and damage the internal components.

But to fully understand this failure mode, it helps to define a few related concepts:

- Compression Force Deflection (CFD):

CFD measures how much force (in PSI or kPa) is required to compress a foam to a certain percentage of its thickness. It gives insight into how soft or firm a foam is—essentially how easily it compresses. Various ASTM and ISO test methods define how CFD is measured.

For more on CFD, read The Ultimate Guide to Compression Force Deflection + Free Tool. - Density (PCF):

Foam density is expressed in pounds per cubic foot (PCF) and is a measure of weight, not stiffness. A common misconception is that increasing density also increases CFD. That is only true when comparing the same type of foam.

For example:

- Volara® Type A, a cross-linked polyethylene foam at 4 PCF, requires 10 PSI for 25% compression.

- PORON® 4701-30, a high-density polyurethane foam at 15 PCF, requires only 3.1 PSI for the same compression.

Even though the PORON foam is more than three times heavier, it compresses more easily than the lighter Volara—showing that density alone doesn't determine compressibility.

For more on density, read Foam Firmness vs. Density and Why It's Important.

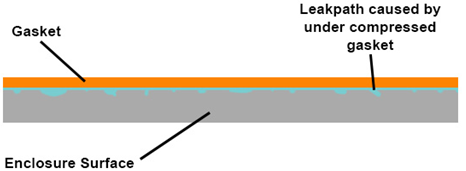

Compression Set (C-Set):

Compression set refers to a material’s inability to fully rebound after prolonged compression. In ASTM testing, a sample is compressed to a certain percentage of its original thickness, held at a specified temperature and duration, and then released. The remaining thickness is measured after recovery, and the compression set is reported as a percentage.

For example, a specimen that starts at 1.00 inch and rebounds to only 0.75 inches has a 25% compression set.

As foam takes on compression set, it loses elasticity and sealing force. This is often accompanied by stress relaxation—meaning the material no longer maintains the force needed to keep the seal intact. A leak is likely to follow.

For more on compression set, read Everything You Need to Know About Compression Set for Elastomeric Foam Materials.

Possible Solutions:

The timeline for a seal to lose effectiveness varies by environment and application, but if long-term performance is critical, it is important to choose materials with strong compression set resistance.

- Use materials like PORON polyurethane or BISCO® silicone, which maintain their shape and sealing performance over time. These high-performance materials can have compression set values below 5%, even in demanding environments.

- In comparison, materials like neoprene, rubber blends, polyethene, and EPDM may show compression set values as high as 50% in high-temperature conditions, leading to early failure.

- Work with Rogers and Marian to evaluate the right material for your environment and validate your design through testing.

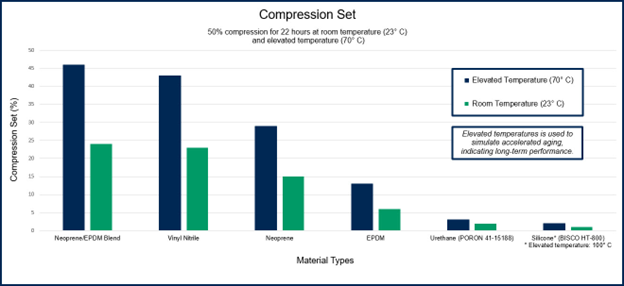

Image property of Marian Inc

Before and after 1 hour under compression: see how different materials like PORON, BISCO, polyethylene (PE), and Neoprene respond under the same load. PE and neoprene take a significant set.

Image property of Rogers Corporation

Bad compression set in the same gasket example as we saw in #1.

3. The Seal Degrades When Exposed to Temperatures Outside Its Rating

Problem:

Seals can degrade over time when exposed to temperatures beyond their recommended range—whether too high or too low. While short spikes in heat may not cause immediate failure, prolonged exposure can cause materials to crack, harden, or lose elasticity.

At the other end of the spectrum, extreme cold can make some materials brittle, leading to similar performance issues. Either way, the result is the same: a compromised seal and a risk of failure.

Possible Solutions:

- Design for the full range of expected environmental conditions—not just ambient. Consider worst-case temperature scenarios in both directions.

- Use materials specifically engineered for extreme temperatures. For example, BISCO silicones maintain flexibility and sealing integrity across a broad operating range from -67°F to 392°F (-55°C to 200°C).

- In contrast, materials like neoprene may become brittle or degrade at temperatures above 250°F (121°C), which increases the risk of failure in high-heat applications.

4. The Seal Wears Down from Repetitive Movement (Abrasion, Vibration, and Cycling)

Problem:

Seals used in moving components—like doors, access panels, or lids—must endure frequent opening and closing or repetitive motion. These dynamic conditions expose the seal to abrasion and mechanical cycling, which can lead to material wear, reduced compression, and eventual failure.

Possible Solutions:

- For dynamic applications, select materials with excellent durability, compression set resistance, and low stress relaxation. PORON polyurethanes and BISCO silicones are engineered to maintain sealing performance through repeated use.

- Test your design under real-world movement conditions. Rogers and Marian can simulate repeated cycles to verify long-term reliability.

Image property of Marian Inc

Repeated opening and closing can wear down the seal, making material selection and design critical for long-term reliability

5. The Seal Degrades from UV and Ozone Exposure

Problem:Outdoor and harsh environments expose seals to ultraviolet (UV) light and ozone—two elements that can break down many gasket materials over time. Prolonged exposure can cause cracking, hardening, or loss of flexibility, eventually leading to seal failure.

Solutions:

- Choose materials with strong resistance to UV and ozone. Neoprene offers basic protection, while EPDM and high-density polyurethanes like PORON perform better. For the longest-lasting durability in outdoor conditions, silicone sponge and foam, such as BISCO silicones, are typically the best choice.

- Validate material selection through environmental simulation testing. Rogers and Marian can help ensure your gasket design meets the conditions your application will face.

6. The Seal Fails Due to Chemical Degradation

Problem:

When a gasket is exposed to incompatible chemicals, it can swell, soften, crack, or degrade, leading to the loss of structural integrity and sealing performance. This is especially critical in environments involving oils, solvents, or aggressive cleaning agents.

Possible Solutions:

- Refer to material manufacturer chemical compatibility charts for guidance. These charts often indicate whether a material is "recommended" or "not recommended" for use with specific substances.

- If chemical exposure is a critical factor, be specific. Identify the exact chemicals involved, their concentration, and how they will contact the seal (immersion, vapor, splash). Rogers and Marian can then provide tailored material recommendations or test data.

- For extreme chemical environments, consider using fluorosilicones, which offer excellent resistance to fuels, solvents, and harsh fluids.

Key Points

Design decisions and assembly practices play a major role in gasket performance. Poor compression set resistance, over or under compression and inadequate chemical resistance can all lead to premature failure making material selection critical to the success of any design.

By addressing these issues early in the design phase and working closely with trusted partners like Marian and Rogers, engineers can reduce rework, increase reliability, and improve long-term sealing success.

Coming up next: Why seals fail—even after selecting the right material.

In the next blog, we’ll explore how design decisions and installation practices can compromise even the most reliable materials. From gasket geometry to fastener placement and venting, learn how to avoid the subtle but costly mistakes that lead to seal failure.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute™

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute™ —a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for the Enclosure Institute™?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an Enclosure Institute Essentials Kit upon completion, recognizing your expertise

The Enclosure Institute™ is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design:

Not ready to enroll yet?

Explore more blogs on enclosure design best practices:

- Introducing the Enclosure Institute™: Expert Tools to Design Better Enclosures

- Fundamentals of Enclosures: Applications, Sealing, and Protection

- Enclosure Seal and Gasket Standards Made Easy

Your Trusted Partners in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Contact Marian

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Published on Jun 11, 2025