Benefits

- Low inductance

- Controlled partial discharge

- High current and voltage capabilities

- Compact and flexible

- Fully customized

- Possibility of component integration ( e.g. Capacitors )

- Wide range of products tailored to specific power density and inductance

What is a Busbar?

A laminated busbar is a multilayer construction of conductors: copper or aluminum separated by thin dielectric materials, laminated in one structure. Electrically, it is a multilayer electrical circuit that distributes the electrical current from capacitors (buffer) to power modules (IGBT) through specific connections.

Busbar Roles in Power Applications

Busbars are metal bars designed for carrying large amounts of current. Often made of copper or aluminum, every home electrical panel has busbars to distribute ac power to the rows of circuit breakers. Busbars are engineered for power distribution. They are made of copper or aluminum layers separated by insulating materials and laminated into a single structure. Designers choose ROLINX busbars for the quality and reliability, electrical and mechanical expertise, co-engineering and flexible lead times and wide applications to high-power markets, including EV/HEV, rail and renewable energy. They are used in the most demanding applications including mass transit and electric propulsion, industrial drives, renewable energy and automotive systems.

Why Choose ROLINX Busbars?

ROLINX busbars are constructed and manufactured laminated busbars that meet the strictest requirements for railway drive converters, network, wind and solar converters, as well as drives for industrial applications. They have a low inductance, controlled partial discharge, high current capacities and compactness.

Best-in-class Support

- Design engineering support from concept to production

- Responsive and reliable commercial support from quoting through after sales support

Manufacturing Technology Leadership

- 40+ years of busbar manufacturing

- Highly automated from end to end

- Leading-edge quality systems

Integrated Solutions Provider for Power Distribution

- Full range of laminated and powder coated busbars

- Integrated connectors, cables, circuitry and low inductance DC link capacitors

Products

ROLINX® CapLink Solutions

- Unique soldering process mounts capacitors to ROLINX laminated busbars

- Produces small, lightweight assemblies with extremely low inductance and high power density

- Supports SiC technology

ROLINX® Compact

- Most optimal connection solution for high power distribution in very limited space

- Uses powder coating as outer insulation instead of insulation films, allowing for even greater compactness than a laminated busbar

- Easy and quick to install

- High power density capabilities and high temperature resistance

ROLINX® Easy

- Most cost-efficient, simplified busbar solution

- Designed to replace stacked busbars and simplify the supply chain

ROLINX® ECO

- Aluminum construction with non-plated AL1000 conductors with nickel plated AL6000 bushings merged with laser welding

- Light weight and cost-efficient alternative to copper busbars

- Higher performance compared to existing aluminum busbar solutions

ROLINX® Flex

- Flexible busbar with pure copper laminates

- Offers flexibility for customized solutions

- Space saving, easy and quick bending

- Available in standard and customized length

ROLINX® Hybrid

- Combination of power and signal (logic) electronics on a single circuit

- One-piece busbar solution reduces installation time and eliminates wiring errors

- Simplifies the supply chain with a single-piece solution

- Features integrated connectors and surface mount components

ROLINX® Performance

- State-of-the-art laminated busbar technology for demanding, high power applications

- Provides optimized inductance and controls partial discharge

- Shaped to fit high voltage applications

- Compact design

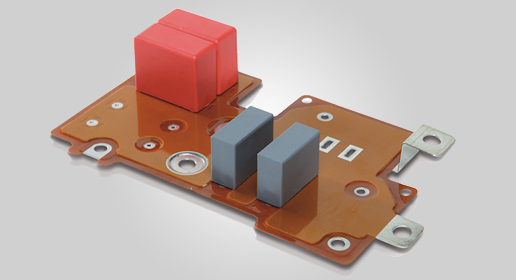

ROLINX® PowerCircuit Solution

- Combines the advantages of PCB and laminated busbar

- Meets the needs of low power applications with currents greater than 100 Amps

- Fit for high volume assembly processes and interconnection techniques

- Compact 3D design & wave soldering capability

ROLINX® Thermal

- Enables existing power system design to be upgraded to a higher power level

- Extended temperature 130 deg. C range and humidity rating

- Allows for more power through the same copper section

Downloads

Applications

View current applications of this product line.

- Auxiliary Systems

- Battery Energy Storage Systems

- Battery Pack & Battery Cell Interconnections

- Charging Stations

- Converter & Inverter Connections

- Converters for Wind Turbines & Solar Farms

- Electric Motors

-

eTrucks, eBusses,

Forklifts - EV/HEV Converters, Inverters & Electric Powertrains

- Power Converters & Power Inverters

- Propulsion Systems

- Routers, Switches and Data Servers

- Smart Grid: Transmission & Distribution

- Solar Inverters

- Telecom and Datacom Cabinet Connectors

- Vehicle Electrification

- VFD and UPS