Published

by Rogers Corporation

Enclosure Institute, Elastomeric Material Solutions

Welcome back to the Enclosure Institute™, an educational series dedicated to helping engineers navigate the complexities of enclosure sealing.

Disclaimer: While this series provides valuable guidance on enclosure design and material selection, every application is unique. We encourage you to contact the Marian team directly for tailored recommendations and expert support.

For our fourth blog, we’re diving into the key considerations for designing effective seals for your enclosures.

From environmental considerations to material compatibility and long-term durability, here are eight helpful insights into designing seals that stand the test of time.

Because let’s face it: if it doesn’t seal, it’s not really an enclosure.

Top 8 Enclosure Design Considerations

1. Environmental Conditions

The environment in which your enclosure operates impacts the type of seal you need:

- Location: Consider the specific location of your enclosure. Enclosures located outdoors will likely deal with a much wider range of conditions versus an indoor enclosure.

- Weather: Assess the conditions the enclosure will be exposed to, including extreme temperatures or weather elements (wind, UV exposure) if located outdoors.

- Ozone: Evaluate potential exposure to high levels of ozone from nearby electric motors and switchgear.

- Fire Resistance: Check if there is a requirement for a flame rating based on the environment in which the enclosure is located.

2. Compatibility

Your gasket material needs to be compatible with whatever it is sealing in or out of your enclosure.

- Examples: Dust, water, light, harsh chemicals, or electromagnetic waves.

- Resources: A reputable material supplier should be able to provide you with comprehensive material compatibility data. For example:

PORON Polyurethane Chemical Resistance Guide

3. Enclosure Access

Consider how frequently your enclosure will need to be opened.

- Never opened: Consider an inexpensive closed cell foam with an adhesive on both sides.

- Occasionally opened: You’ll want a material with a good compression set resistance to ensure the seal performs as intended.

- Frequently opened: Conducting a compression cycling test can help ensure the material withstands repeated use. Both PORON® and BISCO® materials are industry leaders in compression set resistance and long-term cycling performance.

4. Enclosure Material

- Enclosure Housing

The materials and construction of your enclosure can influence how well it seals. A seal must need to be compressed by a certain percentage to form a good seal.

Consider an enclosure with a 2' x 4' door and a ½" wide seal running around its perimeter—that’s 72 square inches of sealing area. Using a material with a compression force deflection (CFD) of 5 psi would require 360 pounds of force to compress the seal by just 25%.

That’s enough force to bend thin-gauge steel.

When the enclosure material deforms, it alters the compression on the seal—leading to potential sealing failures.

Understanding the strength and rigidity of your enclosure material is critical to selecting a gasket with the right softness. You may also need to reinforce the sealing area using thicker materials or structural ribs to ensure consistent compression and reliable sealing performance.

- Tolerance Stack-up

It’s also important to know the stack-up of tolerances for your sealing area. If the door and the enclosure can both vary by 1 mm, the sealing gap may vary by 2 mm total. To ensure your seal will be compressed by between 30% and 50%, that 20% difference can be no more than 2 mm stack up of tolerances. As such, your foam will need to be at least 10 mm thick.

5. Width versus Thickness of a Gasket Seal

We recommend that a gasket should be, at a minimum, as wide as it is thick.

- If you have very tight space requirements on your total enclosure, a 1:1 ratio of thickness to width may be sufficient.

- If you have less confined space requirements, we recommend the width to be 1.5x the thickness of your gasket.

6. Flange or Blade Seal

- A flange seal mates two flat surfaces that are wider than the seal. These are the most common seals and can be designed to easily compress a seal between 30% and 50%. They are especially good at sealing when surfaces may have some roughness or tilt.

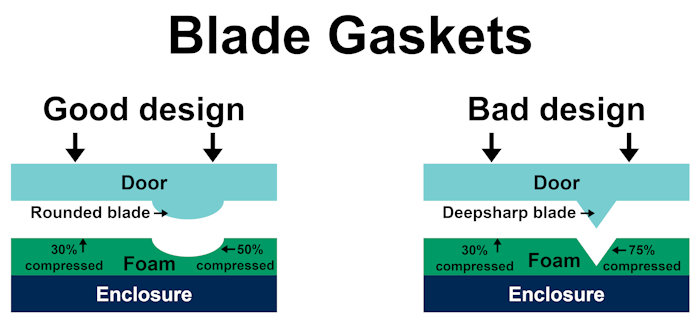

- Blade seals have an edge on one side of the seal rather than a flat surface. They are generally used when a seal must be compressed significantly, or when a reduction of the seal area is needed to reduce the closure force. Care must be taken to design the blade depth so that it does not damage the seal material.

Here is a side-by-side comparison of what good and bad seal designs look like.

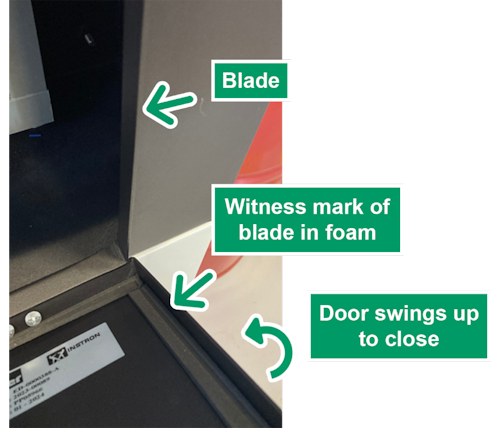

Here are some real examples of what good and bad seal designs look like in practice.

This is an example of a poor sealing design. It over compresses the gasket with the blade.

This is an example of a good sealing design. It compresses the gasket just right.

7. Venting

If you are sealing, chances are that you may need to consider venting solutions.

- Vents equalize pressure inside and outside the enclosure, which prevents structural deformation.

- Types of vents:

- Burst vents: Solid films that rupture under high pressure.

- Pressure equalization vents: Membranes allow steady airflow while blocking dust and water.

- Dual-stage vents: Combine both features

8. Longevity & Dependability

Is your material made to outlast your application? If not, it should be.

The longevity of an enclosure seal depends on designing in a material that can outlast the application.

High-performance open-cell silicones and polyurethanes are often designed for long-term field use. Compared to closed-cell rubbers or cross-linked polyethylene, these materials offer superior compression set resistance and compression force deflection—two key indicators of long-term sealing reliability.

Key Takeaways

- Environment matters: Match your sealing material to the environmental demands, including temperature, moisture, and ozone exposure.

- Material choice drives performance: Use high-performance materials like open-cell silicone or polyurethane for better compression set resistance and long-term reliability.

- Design impacts sealing success: Consider enclosure strength, gasket compression, tolerance stack-up, and access frequency when choosing your seal.

- Sealing shouldn’t be optional: A well-sealed enclosure protects your components and defines long-term product performance — because if it doesn’t seal, it’s not really an enclosure.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute™

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute™ —a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for the Enclosure Institute™?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an Enclosure Institute Essentials Kit upon completion, recognizing your expertise

The Enclosure Institute™ is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design:

Not ready to enroll yet?

Explore more blogs on enclosure design best practices:

- Introducing the Enclosure Institute™: Expert Tools to Design Better Enclosures

- Fundamentals of Enclosures: Applications, Sealing, and Protection

- Enclosure Seal and Gasket Standards Made Easy

Your Trusted Partners in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Contact Marian

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Published on May 07, 2025

Elastomeric Material Solutions

High reliability silicones, polyurethanes and foams for cushioning, sealing, impact protection and thermal management solutions.

Institute Insight

Institute Insight