Published

by Rogers Corporation

Elastomeric Material Solutions

In Part 1, we introduced the basics of PTFE and UHMW-PE materials, discussed key processes like sintering and skiving, explored how these affect material performance, and talked about bread a lot.

In Part 2, we’ll go a step further—reviewing how DeWAL(R) materials are further modified through advanced processes like expansion, conductivity enhancement, and adhesive application to serve even more specialized needs. Don’t worry, there’s bread.

A Continuation of our Bread Analogy

Just like basic dough can be transformed into different foods—like a baguette, a pretzel, or a calzone—DeWAL materials can be adapted to create specialized solutions tailored for durability, flexibility, conductivity, or bonding needs. It all depends on the final form or performance characteristics the application demands. Jalapeño and cheddar sourdough bread, anyone?

In addition to being offered in sintered or unsintered, extruded or skived versions, PTFE and UHMW-PE can also be modified in various ways to achieve the most ideal physical properties for specific applications. Properties like conductivity can be added, materials can be expanded for breathability, or adhesives can be applied to broaden the range of uses these tapes and films can support.

Expanded PTFE (ePTFE)

Definition:

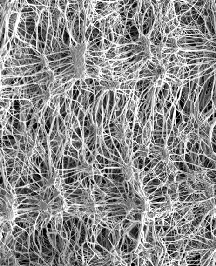

Expanded PTFE (ePTFE) is produced by mechanically stretching (aka expanding) PTFE. This process gives it a unique combination of properties, including breathability, strength, flexibility, thermal stability, and chemical resistance.

The ePTFE structure balances air flow and resistance to water entry pressure (WEP). Simplified, this is precise air permeability without water ingress, making it valuable for demanding filtration and gasketing needs.

How to think about it: ePTFE needs to be made with an unsintered material (dough, remember?). If you have ever worked with dough, you probably have stretched it out enough to see the center get very thin or even translucent; this is similar to how ePTFE is made. However, the process of making ePTFE is VERY controlled, with the goal being to stretch the material to the point that it allows a specific amount of air to pass through while balancing ingress from water.

How to remember it: ePTFE is like dough that has been stretched.

Where it is used: Venting, medical, wire & cable, and battery separators just to name a few.

Expanded PTFE is like dough that is stretched to reveal a porous-like structure.

Conductive vs. Non-Conductive Films

If you’ve ever baked bread, you know how adding ingredients like herbs or spices can completely change the flavor. That’s similar to how adding conductive fillers changes the properties of a film. Depending on what you add, you’re giving the material new characteristics that serve a specific purpose—just like customizing a recipe to get the result you want.

Definition:

Depending on the application, electrical properties can be added into PTFE or UHMW-PE films, just like sprinkling in those secret ingredients into dough; this will change the final product.

Think back to bread:

If you add seeds or cheese into your dough, it will take on new characteristics—flavor, texture, even how it bakes. Similarly, when conductivity is added to a material, it transforms its performance for specific needs like static dissipation or shielding.

- Conductive Films:

Just like adding salt boosts the conductivity of dough (it really does), conductive films are designed to allow the flow of electricity. These materials are used for shielding, grounding, or static dissipation applications where electrical pathways are necessary. - Non-Conductive Films:

In contrast, non-conductive films are like basic bread without additives—designed to insulate, protect, and maintain separation. These films insulate electricity, shielding sensitive components from interference.

Choosing the correct type—conductive or non-conductive—is critical to ensuring optimal performance and safety in electrical and industrial applications.

How to remember it: Do you need conductivity or static dissipation?

Where it is used: Conductive films are used for static dissipation or grounding, while non-conductive films are used for electrical insulation.

Putting additives in or on your bread to change the flavor (like pepper to add some spice) is like adding carbon to a film to make it conductive.

Pressure-Sensitive Adhesives (PSA)

Definition:

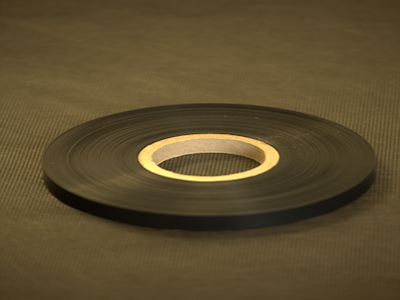

A pressure-sensitive adhesive (PSA) is an adhesive that forms a bond when pressure is applied, without the need for heat or solvents. PSAs are popular for industrial applications because they allow quick, easy, and reliable installation across a range of surfaces.

Rogers offers a variety of DeWAL tapes with PSA backing, making it easy to install PTFE and UHMW materials quickly and securely across a wide range of industrial applications.

How to think about it: Think of PSA like adding a glaze or butter after the bread is baked. The bread (or tape) is already formed, but the finishing layer gives it extra functionality—whether that's shine, flavor, or, in the case of tapes, the ability to bond to a surface.

How to remember it: Pressure sensitive adhesive is like frosting that you put on your cinnamon bun.

What we call it: Films with adhesive are referred to as tapes, not to be confused with what some may refer to as unsintered PTFE tape, which does not have adhesive. Confused yet?

Where it is used: PSA tapes are used in a variety of applications that require the film to adhere to a surface, such as securing a bundle of cables.

Film that has a pressure-sensitive adhesive is like a cinnamon bun after frosting is applied.

| ePTFE | Conductive | Non-conductive | PSA Tapes |

|---|---|---|---|

|

|

|

|

| Example: DeWAL 233MS | Example: DeWAL 103 | Example: DeWAL 202 | Example: DeWAL FST |

Applications:

|

Applications:

|

Applications:

|

Applications:

|

#StickwithDeWAL

Whether you're looking for breathable expanded PTFE, conductive films for shielding, or the convenience of PSA-backed tapes, Rogers offers specialized DeWAL solutions built for real-world performance. Find more information about Rogers DeWAL products.

Understanding the basics behind these materials and their modifications will help you design smarter, more reliable products. For more detailed product information, connect with a Rogers Sales Engineer today.

Related Content

- DeWAL® Materials 101: Understanding PTFE and UHMW-PE for High-Performance Tapes and Films

- Top 5 Things You Might Not Know About PTFE Tapes

- The Engineer's Toolkit: 8 Best Tools for Effective Material Selection

Published on Sep 18, 2025