Published

by Rogers Corporation

Elastomeric Material Solutions

Do silicones expire? Can you still use old sheets of foam or solid silicone? And what happens if adhesives are involved?

We will answer some common questions engineers have about the use and storage of BISCO® silicone materials so you can make smart decisions in the lab or on the factory floor.

We will also provide tips and tricks to help maintain product quality and ensure optimal material performance.

Does silicone expire?

Silicone does not expire in the traditional sense, but it does have a manufacturer-recommended shelf life.

The good news is that silicone has a relatively long shelf life compared to other materials, especially when stored properly.

Why is the shelf life of silicones important?

Understanding shelf life helps ensure:

- Consistent performance

- Reliable adhesion

- The avoidance of costly failures

Image property of Rogers Corporation

What factors impact the shelf life of cured silicone material?

The shelf life of silicone depends on different factors including:

- Adhesive type (acrylic or silicone)

- Post-processing procedures (slitting, laminating)

- Storage conditions (temperature, humidity)

- Packaging integrity

Shelf-Life Guidelines for BISCO Silicones

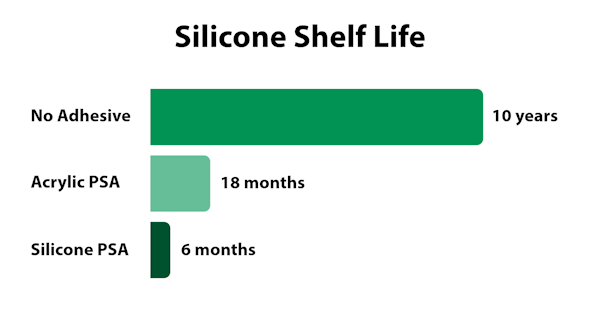

What is the shelf life of BISCO Silicones without adhesive?

Shelf life: 10 years from the date of manufacture

BISCO silicones show little to no physical degradation for long periods, making them a stable and reasonable material to stock. If stored in standard conditions, the shelf life for BISCO products without adhesive is 10 years from the date of manufacture.

The shelf life may vary once the material has been altered, such as if it is slit, laminated, or kept in extreme storage conditions.

What are the recommended methods to store BISCO silicones?

Here are our top three tips for storing silicones without adhesive:

- Keep in original packaging until ready to use.

- Store in an environment of 60°F to 80°F (16°C to 27°C) and relative humidity of 40% to 75%.

- Keep material out of direct sunlight.

What is the shelf life of BISCO silicones with adhesive lamination?

Silicones with adhesives have shorter shelf lives, with the adhesive being the limiting factor.

Shelf life (stored at standard conditions stated above):

- Acrylic-based pressure sensitive adhesive (PSA): 18 months from date of lamination

- Silicone-based pressure sensitive adhesive (PSA): 6 months from date of lamination

Typically, silicone materials are laminated within a few days of shipment and will have more than 80% of the shelf life when shipped to a customer.

Please note that adhesives are not manufactured by Rogers Corporation and have their own respective shelf life. Please consult with your Rogers Sales Engineer for more information about the adhesives used in laminating BISCO silicone materials.

Can you use silicone without adhesive that is past its recommended shelf life?

If you have silicone that is past its recommended shelf life of 10 years (without adhesive), the material may be tested to verify the physical properties such as compressive force deflection, tensile strength, elongation, and compression set.

You can then compare the test result values to technical data sheets.

Depending on the application requirements, if the test results are within spec and no significant degradation of properties occurred, the material may still be utilized past its recommended manufacturing shelf-life date.

Considerations for silicone with adhesive that is past its shelf life

Silicone materials with adhesive lamination present other issues that bear consideration. Here are the possible issues of silicone with adhesive lamination being past its shelf life:

- Peel strength may degrade:

Adhesive may no longer have the same anchorage strength and might not stick securely to the material to which it is intended to bond.

We recommend testing the material for peel strength or sheer creep in this case. - The liner paper or PET might become tight or shrink:

The liner paper or PET becoming tight or shrinking could make it difficult or impossible to remove the liner and expose the adhesive. This would make the material unusable.

Consult with a Rogers Sales Engineer to discuss test methods, results, and recommendations for your specific case.

Can I stack silicone foams, solids, or buns to take up less storage space?

Silicones should not be stacked directly on top of each other, as this could cause an effect known as "blocking."

Blocking can occur when the two surfaces are in direct contact, allowing the polymer to try to bond with the unprotected surface. BISCO silicones come with either a PET liner on cellular foam materials or kraft paper on non-talc solid materials to prevent the materials from blocking.

If the PET liner is removed and the product is stacked upon itself, there can be light bonding between the surfaces, which may lead to tearing of the foam surface or bonding of solid sheets.

Once the protective liner is removed, Rogers Corporation does not recommend stacking the material directly without an aid to prevent the blocking effect.

The following are typical barriers to reduce blocking:

- PET polyester film or kraft paper interleaves between layers

- Talc, or dusting of the surface

Key Takeaways

- BISCO silicones have a 10-year shelf life without adhesive, assuming proper storage

- Laminated materials follow the adhesive’s shelf life (6–18 months)

- Use appropriate storage and handling practices to extend performance

- Test older material to verify physical properties before use

- Contact a Rogers Sales Engineer to review test methods/results, storage recommendations, or for any questions.

Related Content

- Top 7 Unique Silicone Advantages You Can't Ignore

- How to Choose a Reputable Silicone Supplier: Top 6 Tips

- Let's Compare: Silicone vs Polyurethane vs EPDM and More

Published on May 14, 2025