Release Date: 04/12/2022

Eschenbach, Germany, March 29, 2022 – Rogers Corporation’s (NYSE:ROG) Advanced Electronics Solutions (AES) group will be exhibiting at PCIM Europe and showcasing the whole curamik® ceramic substrate portfolio and ROLINX® Eco which is a new generation aluminum busbar with unique features.

The PCIM Europe (Power Conversion and Intelligent Motion) is the world's leading exhibition and conference for power electronics, intelligent motion, renewable energy, and energy management. The exhibition and conference is the leading international platform showcasing current products, topics and trends in power electronics and applications, taking place at the Nuremberg Messe (exhibition hall) in Nuremberg, Germany from May 10 – 12, 2022. Rogers AES will be exhibiting in Hall 9 at Booth 351.

Rogers AES will also be active on the E-Mobility Forum schedule, with presenter Olivier Mathieu on the topic, “Metallized Ceramic Substrates with Enhanced Performance”. This presentation will show that Direct Bonded Copper (DBC) and Active Metal Brazing (AMB) substrates provide outstanding thermal performance spreading and dissipating heat from power semiconductor devices. Furthermore, the lifetime of multichip power modules will be discussed highlighting the need to survive thermo mechanical stress under operation. Novel design rules will be proposed that optimize the reliability of power modules under thermal cycling conditions. (Thursday, May 12, 2022, 11:10 am, Hall 6, E-Mobility Forum).

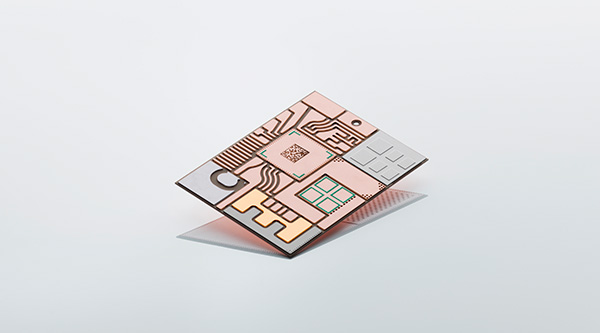

Visitors to the Rogers booth can learn more about curamik® ceramic substrates designed for high-demand applications. The basis of the substrate is a ceramic insulator to which pure copper is applied. The result is ceramic substrates with high thermal conductivity, high heat capacity and heat spreading provided by the thick copper layer. These high-performance substrates are well-suited for power electronics applications.

Visitors will also have the chance to discover the wide range of ROLINX® customized busbar solutions and assemblies renowned for their reliability, safety, and durability in the most demanding applications including mass transit and electric propulsion, industrial drives, renewable energy, and automotive systems. ROLINX® busbar solutions offer low inductance, compact and highly customizable designs and in combination with capacitors, extremely low inductance and high-power density capabilities. Visitors can also learn more about ROLINX® Eco which is a new generation aluminum busbar with unique features such as surface treatment options, bendability, lower contact resistance and creep, compared to traditional aluminum or copper busbars. The applied product range for ROLINX® Eco are single conductor busbars, laminated busbars and multi-layer conductors for high voltage busbars.

Image 1: curamik® Advantage – features for metallized ceramic substrates, Rogers Corporation

Image 2: ROLINX® Eco – new generation aluminum busbar, Rogers Corporation

Become a Member of the Design Support Hub

Rogers brings its more than 40 years of experience with Power Electronics Solutions together in a handy online resource that is available 24/7. The AES Design Support Hub features complete technical information on ROLINX® busbars, capacitor busbar assemblies and curamik® ceramic substrates, a library of technical papers on product design and problem solving and helpful videos on products and power distribution topics. Registration for access is quick and free of charge. The Design Support Hub provides information to help design engineers increase power, manage heat, and ensure the quality and reliability of their devices for optimal new product design (www.rogerscorp.com/designhub).

About Rogers Corporation

Rogers Corporation (NYSE:ROG) is a global leader in engineered materials to power, protect and connect our world. Rogers delivers innovative solutions to help our customers solve their toughest material challenges. Rogers’ advanced electronic and elastomeric materials are used in applications for EV/HEV, automotive safety and radar systems, mobile devices, renewable energy, wireless infrastructure, energy-efficient motor drives, industrial equipment and more. Headquartered in Chandler, Arizona, Rogers operates manufacturing facilities in the United States, Asia and Europe, with sales offices worldwide. For more information, visit www.rogerscorp.com.