AMB is the substrate of choice in automotive applications, windmill turbines, traction applications and high voltage DC transmissions where high reliability, heat dissipation and partial discharge are required. The high heat conductivity of Si3N4 (90 W/mK), high heat capacity and heat spreading provided by the thick copper layer (up to 800 µm) make curamik ceramic substrates irreplaceable in high power electronics.

The coefficient of thermal expansion of Al2O3 (7.1 ppm/K), Si3N4 (2.6 ppm/K) and AlN (4.7 ppm/K) is close to that of silicon (4 ppm/K). Therefore, Direct Bond Copper (DBC) and AMB are suitable substrates for robust packaging of bare dice since such assemblies are not likely to wear our during the product life.

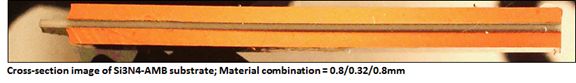

AMB technology offers the option of applying very thick copper metallization (up to 0.8mm) on relatively thin Si3N4 ceramic. This provides very high ampacity and very good heat spreading. Similar to PCBs, layout may be customized.

Our extensive experience in DBC provides the perfect base for supplying high quality AMB substrates of silicon nitride and aluminum nitride. Our existing structuring facilities, automated and manual inspection capabilities, and global sales and support system provide world-class service.

Find out about our other patented technologies at work in our innovative designs: