Published

by Rogers Corporation

Elastomeric Material Solutions

Silicone is a superhero in the world of materials! Not only does it offer stellar performance in a wide range of applications, but it is also versatile, coming in many different forms tailored to meet specific needs.

Silicone most often comes in three fundamental forms:

- Cellular foams

- Cellular sponges

- Solids

Each form has distinctive attributes that play vital roles in a range of applications and industries.

Learn more about silicone form key characteristics and applications from Dan Kubick, Rogers’ Principal Technical Service and Development Engineer, who has more than 35 years of experience in the field.

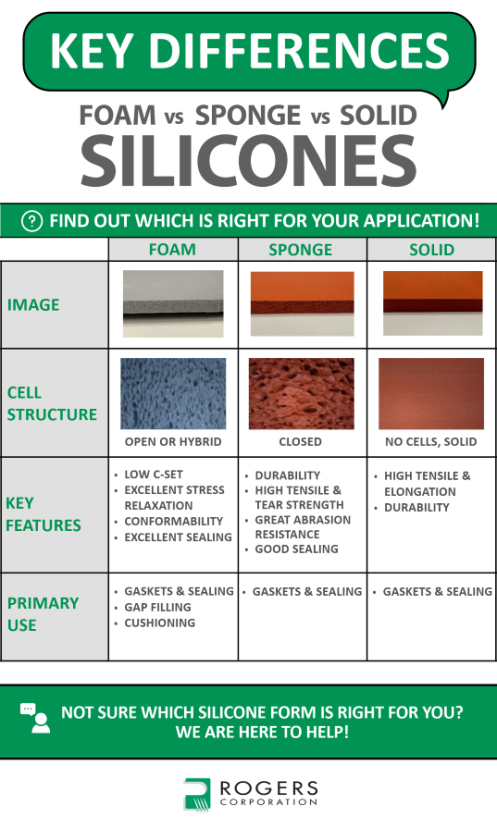

Want a quick visual summary?

What are the Three Most Common Silicone Forms?

As Dan Kubick often says, “the best type of silicone form really depends on your application.”

Let’s take a look at the cell structure, key features, and use case for each of the three forms of silicone:

- Silicone Cellular Foam

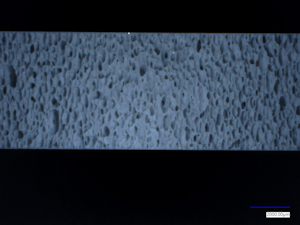

- Cell Structure: Open or Hybrid. Typically, the foam's cells are not totally enclosed by cell walls and open to the surface, either directly, or by interconnecting with other cells.

- Key Features: Cellular foams that have open or hybrid cell structures are known for their exceptional conformability and excellent sealing properties due to their compression set resistance and limited stress relaxation. They are flexible and can conform to irregular shapes, making them great for sealing and protection.

- When to Use Cellular Silicone: Cellular silicone foams are suitable for applications requiring reliable, long-term sealing, such as gaskets and seals in the automotive industry, appliances, and a wide range of electronic enclosures.

- Silicone Cellular Sponge Rubber

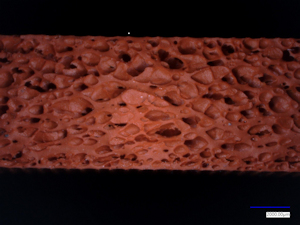

- Cell Structure: Closed. Typically closed cell structure cells are totally enclosed by cell walls and do not interconnect with other cells.

- Key Features: Cellular sponges that are closed-cell silicones are best known for their toughness, durability and excellent sealing properties. They are flexible and can conform to irregular shapes, making them great for sealing and protection.

- When to Use Cellular Sponge Silicone: Cellular sponge silicones are suitable for rugged applications requiring higher strength material, such as gaskets and seals in HVAC and electronic enclosures. Gaskets made from cellular sponge silicone are durable and are better able to withstand surface damage and tear.

- Solid Silicone

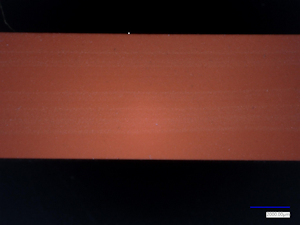

- Cell Structure: No cells. Solids have a uniform, compact structure.

- Key Features: Solid silicones are available in industrial and performance grades with various properties such as tight thickness tolerances, high tensile and tear strength. They are dense and robust, creating a consistent seal since they create a solid barrier without compression.

- When to Use Solid Silicone: Solid silicones are used in applications where durability and precision are essential, such as aerospace, medical devices, and industrial machinery. They are also known for their resistance to extreme temperatures.

Key Features of Different Forms of Silicone: Foam, Sponge, and Solid

| Silicones | ||||

|---|---|---|---|---|

| Cellular Foam | Cellular Sponge | Solid | ||

| Key Features |

|

|

|

|

| Primary Use |

|

|

|

|

| Cell Structure | Open or Hybrid | Closed | No cells, solid structure | |

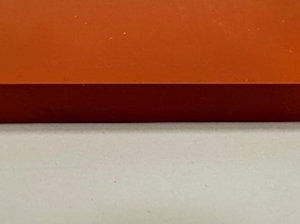

| Visual |  |

|

|

|

| Cell Structure under SEM Microscope |  |

|

|

|

Takeaway

Understanding the different forms of silicone and their properties is essential for selecting the right material for your specific application.

Whether you need flexible and versatile cellular foams, durable and strong cellular sponges, or robust and precise solid silicones, the choice depends on the unique requirements of your project.

Selecting the right silicone form is not always straightforward or easy. That's why designers and engineers rely on Rogers’ product expertise - we are here to help! Speak with a Rogers Sales Engineer to discuss your application needs and determine which form of silicone is right for you. We also offer free material samples to test for fit and function. #RelyOnRogers

Related Content

- Top 7 Unique Silicone Advantages You Can't Ignore

- How to Choose the Right Silicone: Top 6 Considerations

- Let's Compare: Silicone vs Polyurethane vs EPDM and More

Published on Mar 08, 2024