Published

by Rogers Corporation

Enclosure Institute

Welcome back to the Enclosure Institute™.

In our last blog, we explored material — and environment-related reasons why gaskets and seals fail — from compression issues to long-term exposure. In this blog, we are turning the focus to what happens after material selection. Design choices, installation methods, and real-world application factors can all introduce sealing problems that even the best gasket materials can’t overcome. From poor geometry and fastener placement to retention issues and venting, these challenges often go unnoticed until it is too late.

Here are some of the most common design and assembly-related reasons enclosure seals fail and what to do about them.

Overview:

Why Seals Fail – Part 2: Design, Installation & Real-World Causes

| Root Cause | Problem | Possible Solution(s) |

|---|---|---|

| 1. Poor Gasket Geometry | Narrow sealing surfaces, fasteners inside seal path, sharp corners, or multi-piece designs can lead to stress, distortion, or failure. |

|

| 2. Poor Integration or Retention | Gaskets can shift during install or operation, especially in dynamic/vibrating systems. |

|

| 3. Installation or Assembly Damage | Gaskets can be torn, stretched, or misaligned, compromising seal integrity. |

|

| 4. Uneven Compression | Uneven clamping, poor torque, or bad sealing surface causes under-compression and leaks. |

|

| 5. Vibration or Impact | Vibration or shock causes stress relaxation or mechanical fatigue. |

|

| 6. Insufficient Venting | Pressure changes cause seal deformation and failure. |

|

1. The Seal Fails Due to Poor Gasket Geometry

Problem:

Gasket geometry plays a critical role in long-term sealing performance. Poor design choices—such as narrow sealing surfaces, poorly placed fasteners, sharp corners, or multi-piece assemblies—can lead to stress concentrations, distortion, or premature material failure.

Here are four common geometry-related problems and how to solve them:

- The Sealing Surface is Too Narrow Compared to Gasket Thickness

If the sealing surface is significantly narrower than the thickness of the gasket, the material can distort, collapse, or fail to maintain compression under load.

Possible Solution:

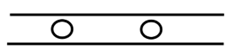

Design with an appropriate width-to-thickness ratio. A minimum of 1:1 is recommended, meaning the sealing surface should be at least as wide as the gasket is thick. For greater dimensional stability and sealing reliability, aim for a ratio of 1.5:1 or more. For example, a 0.25-inch-thick gasket should have a sealing surface of at least 0.375 inches. - Fasteners Are Placed Within the Sealing Surface

When bolt holes or clamping points are located inside the seal path, they reduce contact area and introduce weak spots.

Possible Solution:

Place fasteners and compression points outside of the sealing surface whenever possible. This ensures consistent pressure across the gasket and reduces the risk of leakage or uneven compression. - The Gasket Has Sharp Corners

Sharp or square corners can act as stress risers, making the gasket more likely to tear or crack during installation or under load.

Possible Solution:

Use radiused corners to distribute stress more evenly and improve the gasket’s long-term durability. - The Gasket is Constructed in Multiple Pieces

Large or complex gaskets are sometimes produced in multiple parts due to size, tooling, or cost—but joints can introduce failure points.

Possible Solution:

When possible, design with a single, continuous gasket. If joints are required, consider what we call a “collapsible gasket” that must be carefully opened and installed. Another solution might be what we call a “puzzle gasket” where the joints of the gasket parts fit together like puzzle pieces.

2. The Seal Fails Due to Poor Integration or Retention

Problem:

Gaskets that are not properly secured or aligned during installation can shift out of position, leading to leaks, inconsistent compression, or total seal failure. This issue is especially common in high-vibration environments, dynamic sealing applications, or enclosures that experience pressure changes or thermal cycling.

Possible Solution:

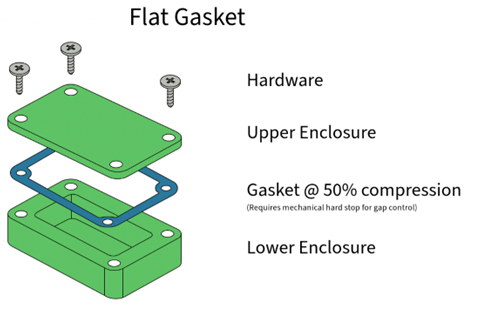

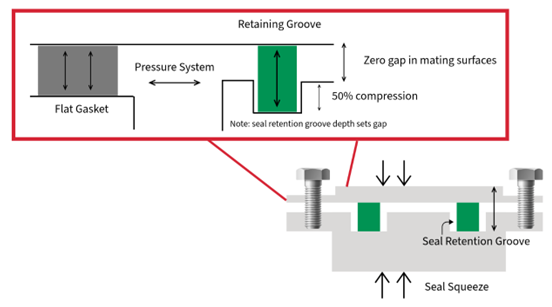

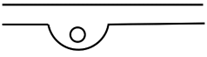

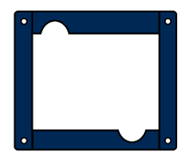

- Use flat gaskets combined with mechanical hard stops to control the compression gap and ensure consistent sealing (a good baseline).

Image Property of Rogers Corporation - For added security, incorporate retention grooves or locating features that keep the gasket in place during both installation and operation (even better).

Image Property of Rogers Corporation - Consider working with Marian to design a gasket presentation that aligns with your assembly process, whether that means parts kiss-cut on rolls or with added pull-tabs or custom liners for easy and accurate placement.

3. The Seal Fails Due to Installation or Assembly Damage

Problem:

Improper installation techniques—such as overstretching the gasket, misalignment during placement, or contact with sharp edges—can cause physical damage that compromises sealing performance. Even a small tear or uneven compression can lead to early failure.

Solution:

- Avoid stretching the gasket during installation. For gaskets with PSA (Pressure-sensitive adhesive) backing, the adhesive layer helps prevent elongation and ensures proper positioning.

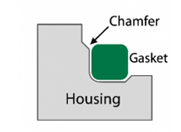

- Add chamfers or lead-ins to housing designs to ease installation and reduce surface damage risks.

4. The Seal Fails Due to Uneven Compression

Problem:

When a gasket experiences uneven compression across its surface, certain areas may be under-compressed and more vulnerable to pressure leaks. This often results from inconsistent bolt torque, poor sealing surface design, or uneven clamping in hinged enclosures.

Solution:

- Ensure even compression during installation. For bolted assemblies, use an alternating bolt-tightening pattern to distribute load evenly.

- In hinged enclosures, add clamping mechanisms or fasteners along the non-hinged sides to maintain uniform compression across the entire gasket.

- During design reviews, work with Marian to identify any risk areas where compression might vary and make adjustments early in the process.

5. The Seal Loses Effectiveness from Vibration or Impact

Problem:

Even in static applications, seals can degrade when exposed to continuous vibration, shock, or other external forces. These conditions may not involve movement of the seal itself, but they can cause gradual material deformation over time. This often results from stress relaxation, where the material loses its ability to maintain sealing force, or from mechanical fatigue that weakens the foam's structure — leading to leaks or failure.

Solution:

- Select materials with strong vibration resistance, low stress relaxation, and long-term elasticity. PORON® polyurethanes and BISCO® silicones are designed to absorb vibration and maintain compression in tough environments.

- Conduct accelerated aging or vibration testing to evaluate long-term sealing performance under real-world stress conditions. Rogers and Marian can assist with both material selection and testing protocols.

6. Insufficient Venting

Problem:

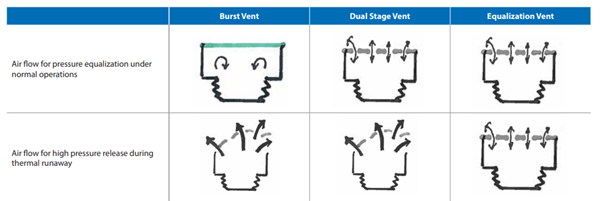

Enclosures exposed to pressure changes can create a vacuum or pressure buildup, causing seal deformation, leakage, and — you guessed it — failure. Without proper venting, repeated expansion and contraction can stress the gasket too much and compromise the seal’s integrity.

Solution:

- Use pressure-equalizing vents for enclosures exposed to significant pressure changes. These vents help equalize pressure, reducing stress on seals and maintaining long-term performance.

- Work with Rogers and Marian to identify the right venting solutions and gasket materials for your specific application.

Image property of Rogers Corporation

Image property of Marian Inc

Example of improper venting on an outdoor architectural light.

Key Points

Many gasket failures are not caused by the material itself—but rather by how it is installed, retained, or integrated into the enclosure design. Poor geometry, inconsistent compression, and lack of venting can all undermine sealing performance, even when high-quality materials are used.

By identifying these common pitfalls early and designing around them, engineers can reduce rework, minimize risk, and improve long-term reliability.

Rogers and Marian are here to help. Whether you need guidance on material selection, design best practices, or testing support, our teams are ready to collaborate and deliver custom solutions for even the most demanding sealing challenges.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute™

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute™ — a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for the Enclosure Institute™?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an Enclosure Institute Essentials Kit upon completion, recognizing your expertise

The Enclosure Institute™ is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design:

Not ready to enroll yet?

Explore more blogs on enclosure design best practices:

- Introducing the Enclosure Institute™: Expert Tools to Design Better Enclosures

- Fundamentals of Enclosures: Applications, Sealing, and Protection

- 6 Reasons Why Gaskets Fail: Materials and Environment

Your Trusted Partners in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Contact Marian

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Published on Jun 18, 2025

Institute Insight

Institute Insight