Published

by Rogers Corporation

Elastomeric Material Solutions

Design engineers have many details to consider when choosing the right materials for advanced applications. Learn more about what makes silicone a material of choice from Rogers’ Principal Technical Service and Development Engineer Dan Kubick, who has over 37 years of experience working in the gasket and sealing field.

What are Silicones?

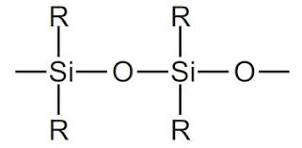

“Silicones” is a popular term to describe a family of organo-silicon compounds based on a backbone (a molecular chain) of alternating silicon and oxygen groups.

Here’s a look at the structure:

Silicone Chemical Backbone

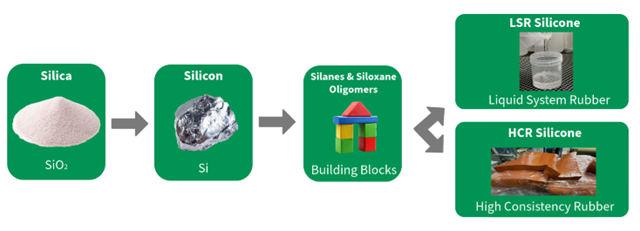

How is Silicone Made?

Silicone is made from silica or quartz, the most common mineral on the earth. Through chemical processing the material is made into oligomers.

Oligomers are the “building blocks” for the raw materials used to produce LSR (Liquid System Rubber) or HCR (High Consistency Rubber) material.

Silicones became commercially available in the 1940s and were designed for use in extreme conditions. They were introduced and used in military aircraft primarily as high-temperature-resistant oils, enabling aircraft to fly to higher altitudes and perform in very cold temperatures. This provided an advantage in air combat since the planes could outmaneuver the enemy aircraft.

Why Should I Use Silicone Material in my Application?

The answer comes down to reliability, as silicone is a highly dependable elastomer available to fill a wide range of applications.

Silicone’s high reliability excels in tough applications that require the material to perform for years. It’s typically used in highly specified applications including aircraft, trains, automobiles, marine, life sciences, and many others.

The inherent properties of UV and ozone resistance mean the material will not break down in most environments, so they are built to last. Additionally, silicone properties do not change across a wide temperature range, meaning a design engineer can use the material in extreme climates such as frigid Alaskan winters or blazing hot summer days in Arizona. Silicones perform in the cold or heat, protecting your critical design.

Depending on how the silicone is formulated, the material can also exhibit great compression set resistance (memory), excellent stress relaxation, or low flammability and smoke generation. These key features make silicone an attractive option for extreme applications in aerospace, defense, electric vehicles (EV), hydrogen vehicles, railways, and general industrial uses.

What is Unique About Silicone?

Silicone’s temperature stability and wide operating temperature range make it a unique material.

Silicone has a broad thermal temperature range from -103 °F up to +482 °F (-75 °C to +250 °C) for continuous usage depending on how the material is formulated. It is one of the only materials that can be used over this wide temperature range without its properties changing during use.

Can Silicone Be Produced in Different Forms?

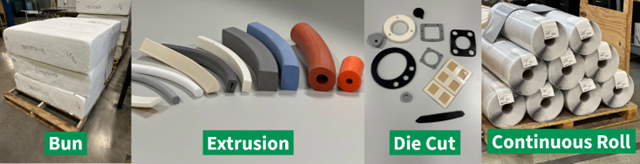

Silicone has many possible manufactured forms: solids, sponge, foams, and buns. Within these forms, it can be calendered, injection molded, cast, extruded, skived, or compression molded to produce a usable material or end product.

Today, silicones can be produced using platinum, tin, or a peroxide-curing catalyst. Of the different curing mechanisms, the platinum-cured products create the most stability from a property standpoint. This is why this technology is often preferred for medical applications requiring a high degree of reliability.

Does Silicone Come in Different Shapes?

Silicones can be produced in many forms, from bun to extruded cords and shapes to continuous rolls. These forms can be further processed by die-cutting or molding to shapes. Technology is available to provide the product in the form needed for any application.

Key Points

Silicone is a versatile and reliable material. Its key features include a wide temperature range, various forms (like solids, sponges, foams, and buns), and stability in extreme conditions, making it ideal for demanding applications in aerospace, defense, electric vehicles, and other industries requiring durable, consistent performance.

In future articles, we will explore the advantages of silicones, uses of the material, and product offerings from Rogers Corporation. To discuss your individual silicone needs, and learn why designers rely on Rogers for our material expertise, please contact a Rogers Sales Engineer. #RelyOnRogers

Related Blogs

- Top 7 Unique Silicone Advantages You Can't Ignore

- Silicone Application and Industry Overview

- How to Choose the Right Silicone: Top 6 Considerations

Published on Mar 01, 2024