Published

by Rogers Corporation

Elastomeric Material Solutions

We know budget is important when designing products, so it is worth considering: could selecting silicone actually save you money in the long run? Read on to learn about the top six long-term benefits of silicone.

First, let's talk about the cost of silicone compared to other materials.

Want a quick visual summary?

How Does the Cost of Silicone Compare to Other Common Materials?

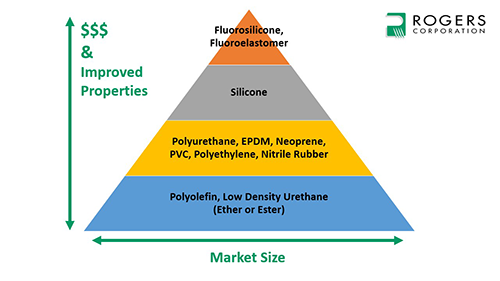

In general, silicone tends to be more expensive than other common materials such as traditional rubber, thermoplastics like polyethylene and PVC, EPDM, and other elastomers (including neoprene and nitrile rubber). It is also significantly more expensive than lower-performance materials such as polyolefins and low-density urethanes (ether or ester).

Silicone is priced comparatively to other high-performance polymers such as polyimides and PTFE/Teflon™, but tends to be less expensive than fluorosilicones and fluoroelastomers.

Below is a general comparison of common material costs. The higher up the pyramid you go, the higher the performance and cost of the material.

Please note that this chart is a general guide for reference. The actual price of materials can vary depending on the formulation, quality, specifications, requirements, and manufacturer.

Requesting a quote from the supplier is the best way to compare the price of silicone to other alternative materials.

Why is Silicone Expensive?

Silicone is expensive for a number of reasons.

- Manufacturing Silica

Making silica (silicone raw material; sand is converted to silica) is a costly process. It is time-consuming, energy-intensive, and involves a lot of expensive components. - Supply Chain Constraints

More recently, global supply chain issues have caused price spikes, significantly increasing the cost of producing silicone. - High-Performance Properties

Despite silicone being more expensive than some other materials, it is one of the best long-term performance polymers. It carries some of the most unique properties, such as temperature stability over a wide range of temperatures. These attributes help justify silicone's cost relative to other elastomeric materials.

Does the High Cost of Silicone Save Me Money in the Long Run?

While silicone may have higher upfront investment costs than other common materials, the long-term savings from its high performance may be worthwhile. We recommend doing a cost-benefit analysis for your project to help determine if silicone makes sense.

Here are some of the long-term benefits you may see from investing in silicone:

- Reduced Cost of Ownership

Silicone is resistant to UV, ozone, radiation, and flame and can handle a wide temperature range. Silicone also has excellent memory and low stress relaxation. All of these properties help reduce maintenance time and replacement costs associated with gasket failures. - Extended Application Life

Silicone is highly durable, thermally stable across a wide temperature range, and resistant to many environmental conditions. Depending on the application, silicone's long-term performance may contribute to extended service life. Use of silicone can minimize corrosion and wear in applications with extreme temperatures or chemical exposure, so less replacement over time is needed. - Improved Reliability

Silicone is known as one of the most reliable materials. This can improve your product reliability, potentially decreasing the number of failures, downtime, and related costs, especially in mission-critical applications. - Improved Efficiency and Performance

In applications where temperature is critical, such as sealing in medical or automotive applications, silicone can help maintain optimal operating temperature. Additionally, its unique properties can contribute to overall better product performance, increasing customer satisfaction and reducing performance-related complaints and costs.

Here are some additional benefits you can expect when you purchase silicones from Rogers Corporation, specifically:

- Regulatory Compliance

Silicone can adhere to strict regulatory and industry standards, such as UL-94 V-0 flame rating or USP Class VI for medical devices. Sourcing material in compliance with important regulations can prevent recalls and legal issues that may be very costly later. Many Rogers Corporation BISCO® silicones meet these stringent requirements. Contact a Rogers Sales Engineer to help you find a material that meets a specific requirement or check out the BISCO Product Properties Tool and filter by "Specification" drop down. - Brand Reputation

The use of high-quality materials can improve the reputation of your product and brand. A positive brand reputation may improve customer satisfaction, loyalty, and support. Designers and engineers have relied on Rogers Corporation, a global materials leader, for over 200 years. Rogers Corporation’s well-known material brands, BISCO®, ARLON®, and Silicone Engineering®. have been trusted in thousands of applications for decades. Learn more about what qualities to look for in a reputable silicone supplier.

Key Points

When deciding whether silicone and the associated cost makes sense for your application, it is important to consider your specific requirements, performance requirements, and the overall cost of maintenance, replacement, and service life. Don't forget to weigh the long-term benefits and potential economic impact over your product's lifecycle.

Contact a Roger Sales Engineer to discuss whether silicone is a suitable material for your application. #RelyOnRogers

Related Content

- How to Choose a Reputable Silicone Supplier: Top 6 Tips

- Top 7 Unique Silicone Advantages You Can't Ignore

- How to Choose the Right Silicone: Top 6 Considerations

Published on Mar 04, 2024