Published

by Rogers Corporation

Elastomeric Material Solutions, Enclosure Institute

Welcome to the Enclosure Institute™, your go-to resource for mastering enclosure design and sealing solutions.

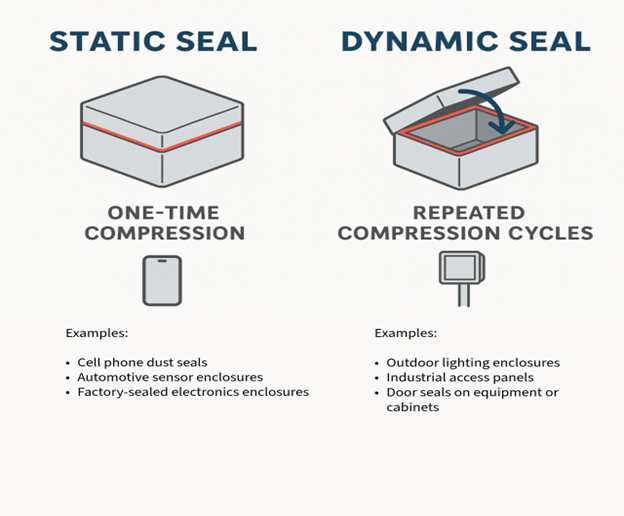

In this blog, we explore a foundational concept in gasket engineering: understanding the difference between static and dynamic seals.

This distinction has significant implications for how a seal is expected to perform over time, and it plays a crucial role in selecting the right materials for durability, maintenance requirements, and long-term enclosure protection.

Understanding Static vs. Dynamic Seals

One of the most important questions to ask in enclosure design is: Will the seal stay closed for most of its life, or will it open and close repeatedly?

The answer determines whether you're designing a static or dynamic seal.

Image property of Rogers Corporation

What is a Static Seal?

A static seal is compressed once and stays in place. It is not designed for regular opening and closing, with servicing only performed by technicians when necessary. Common examples of static seals include:

- Cell phone dust seals

- Automotive sensor enclosures

- Factory-sealed electronics enclosures (ECUs)

Design Implications:

- Priority is placed on initial sealing rather than elasticity over time.

- Material selection should focus on conformability and environmental resistance (e.g., UV, moisture, temperature).

- Compression set matters, but less than in dynamic applications as long as the seal remains undisturbed.

- Adhesive-backed foam or dual-adhesive gaskets are often used for permanent adhesion.

But what if the enclosure is meant to be opened and closed frequently? That’s where dynamic seals come in.

What is a Dynamic Seal?

A dynamic seal, on the other hand, is one that is expected to open and close multiple times while maintaining its ability to reseal effectively. These seals must withstand repeated compression cycles and return to their original shape to ensure long-term performance.

Examples of dynamic seals include:

- Outdoor lighting enclosures

- Industrial access panels

- Door seals on equipment or cabinets

Image property of Marian Inc

Image property of Marian Inc

Design Implications:

- Material must maintain resiliency and elasticity across repeated compression cycles.

- Compression set resistance and stress relaxation are critical.

- Cycle testing and fatigue resistance data become more important.

- Lower closure force materials may reduce stress on hinges or latches.

Key Properties for Dynamic Seals

To ensure long-term performance, a dynamic seal must exhibit the following properties:

- Excellent Compression Set Resistance

- The ability of the material to return to its original thickness after repeated compression.

- Test method: ASTM D395

- Low Stress Relaxation

- The ability to maintain sealing force over time while compressed, preventing leaks and loss of effectiveness.

- Test method: ASTM D6147 or ISO 3384

- Fatigue Resistance

- Ensures the material can survive repeated flexing and mechanical stress.

These properties work together to ensure that each time a dynamic seal is compressed and released, it performs like new. In contrast, materials with poor compression set resistance and high stress relaxation may lose their sealing capability after repeated use—leading to gaps, leaks, and reduced protection.

Mechanical Design Tips for Dynamic Seals

Dynamic sealing introduces several mechanical challenges:

- Uneven compression due to hinges or latches

- Limited closure points that concentrate force in only a few areas

- Warping or distortion in lightweight or plastic enclosures under stress

A common design example is an access panel with two hinges and a latch—similar to a door. In these cases, the sealing force is only applied at three points instead of continuously around the perimeter. If the enclosure lacks sufficient rigidity, the panel may warp or lift at the corners, creating leak paths.

Best Practices:

- Use low-closure-force foam to minimize stress on the housing

- Select a thicker sealing material to accommodate tolerance stack-up and reduce the risk of leaks at corners

- Test the gasket under realistic compression, cycle count, and temperature conditions

Matching the Right Material to the Right Application

A successful sealing design depends on balancing enclosure requirements with material performance. Materials like PORON® polyurethanes and BISCO® silicones offer excellent compression set resistance and low stress relaxation, making them ideal for both static and dynamic applications.

By selecting the appropriate material, engineers can ensure long-lasting, reliable sealing performance, whether the application demands a one-time factory seal or a reusable enclosure that opens and closes regularly.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute™

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute™ — a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for the Enclosure Institute™?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an Enclosure Institute Essentials Kit upon completion, recognizing your expertise

The Enclosure Institute™ is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design:

Not ready to enroll yet?

Explore more blogs on enclosure design best practices:

- What Good Sealing with the Right Partner Looks Like

- Introducing the Enclosure Institute™: Expert Tools to Design Better Enclosures

- Fundamentals of Enclosures: Applications, Sealing, and Protection

Your Trusted Partners in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Contact Marian

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Published on Aug 06, 2025

Institute Insight

Institute Insight