Published

by Rogers Corporation

Enclosure Institute, Elastomeric Material Solutions

Welcome to the Enclosure Institute™, your go-to resource for mastering enclosure design and sealing solutions.

What Makes a Gasket Reliable Over Time?

That’s a deceptively complex question. Most materials can seal well right after installation, but what about after 5, 10, or even 15 years in the field?

In critical enclosures like signal boxes, control modules, or telecom cabinets, long-term sealing performance is essential to prevent failures and reduce maintenance.

In this blog, we’ll explore how different materials hold up over time, how polymers degrade in harsh environments, and what it really means to design for sealing reliability not just on day one, but for the long haul.

Defining “Long-Term” Reliability in Sealing Materials

When we talk about long-term reliability, we’re really talking about material stability over time. It’s not just about how a polymer performs when it’s first installed, it’s about how it holds up after decades of continuous exposure to oxygen, moisture, chemicals, and temperature swings.

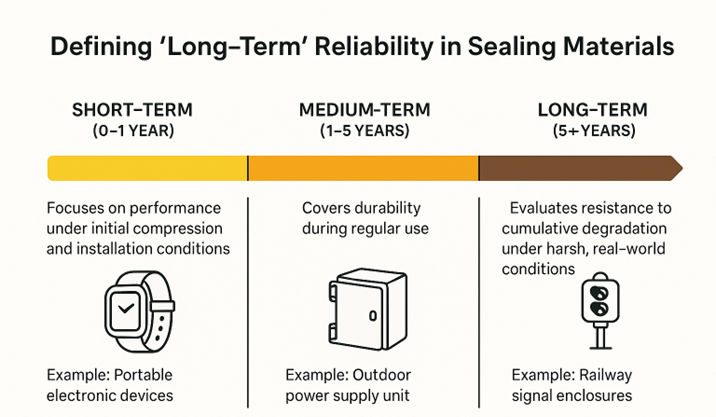

To better evaluate sealing performance, it’s helpful to break it down into three time-based categories:

- Short-Term (0–1 year): Focuses on performance under initial compression and installation conditions. The gasket must seal effectively through handling, assembly, and early operation.

- Example: Portable electronic devices, such as handheld diagnostic tools or consumer wearables, often have a short service life. The seal must work reliably right out of the box but doesn't necessarily need to withstand years of environmental stress.

- Medium-Term (1–5 years): Covers durability during regular use, including temperature cycling, UV exposure, minor mechanical flexing, and environmental fluctuations.

- Example: An outdoor power supply unit or control box expected to function for multiple seasons without material failure.

- Long-Term (5+ years): Evaluates resistance to cumulative degradation under harsh, real-world conditions. This includes prolonged UV exposure, oxidation, hydrolysis, chemical attack, and mechanical fatigue- all without seal failure.

- Example: Railway signal enclosures or infrastructure electronics in remote locations, which may remain untouched for a decade or longer. These types of enclosures require gasketing materials that can maintain performance over years without maintenance or refurbishment.

Image property of Rogers Corporation

This framework is critical because many materials that appear “good” on a technical data sheet or perform well initially may begin to degrade when subjected to long-term exposure to environmental factors. Understanding how materials age is key to ensuring years of performance in the field.

Long-term success depends on understanding not just how a material performs today, but how it will perform years from now in the field.

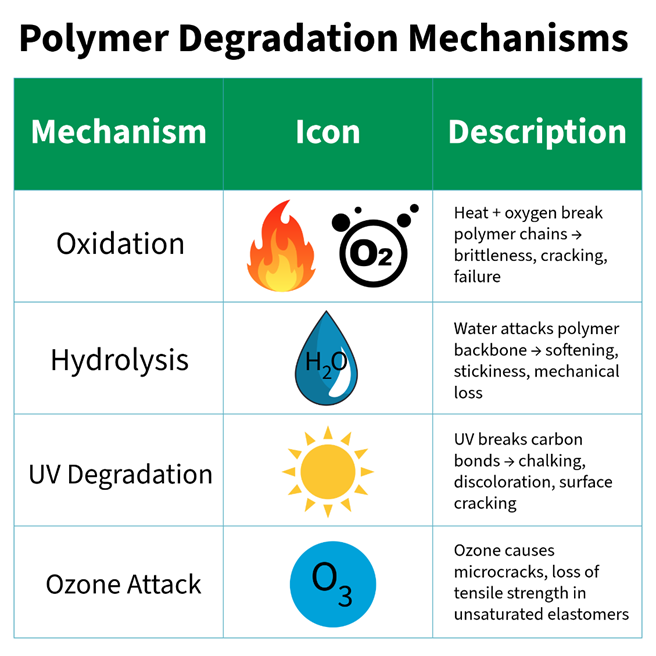

Polymer Degradation Mechanisms

What causes materials to fail over time? Here are the most common degradation pathways that threaten sealing performance:

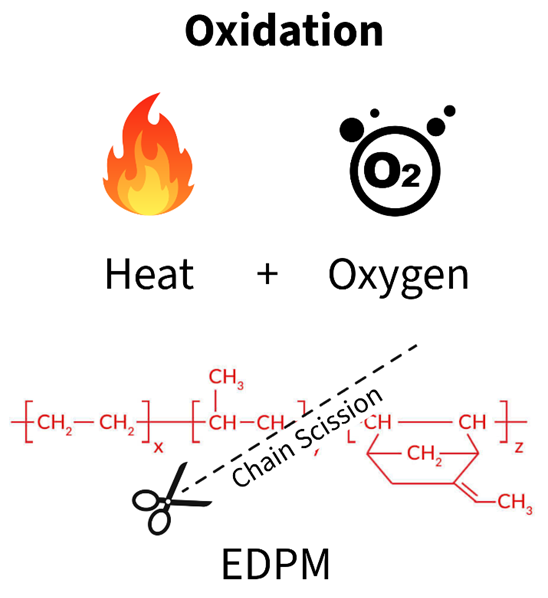

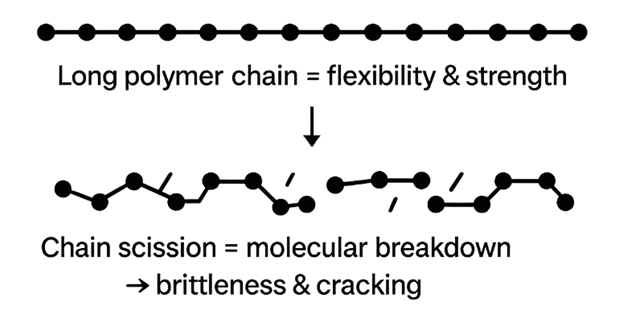

Oxidation

Oxidation occurs when polymers react with heat and oxygen, leading to chain scission, a breakdown of the polymer backbone which reduces molecular weight. This causes brittleness, cracking, and eventual sealing failure.

Image property of Rogers Corporation

Materials with unsaturated bonds, like EPDM or nitrile, are more prone to oxidation. Preventing oxidation is especially important in high-heat environments like lighting enclosures and power inverters, where material degradation can compromise long-term sealing performance.

- Test Methods: UV and Heat Aging (ASTM G154 / D573): Simulates long-term outdoor and thermal exposure.

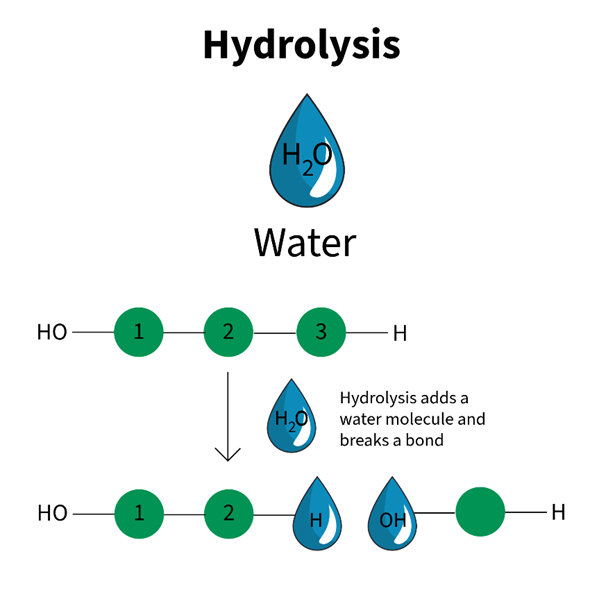

Hydrolysis

Hydrolysis is a chemical reaction where water breaks down susceptible bonds in the polymer backbone, typically natural rubber, butyl rubber, nylon, and some urethane linkages. This leads to softening, tackiness, and eventual loss of mechanical integrity. Polyesters and certain polyurethanes are especially vulnerable.

However, PORON® polyurethanes are engineered to be highly resistant to hydrolysis, making them well-suited for demanding environments where moisture exposure is a concern. Hydrolysis is a key concern in humid or moisture-cycling environments, such as those found in coastal telecom or underground enclosures.

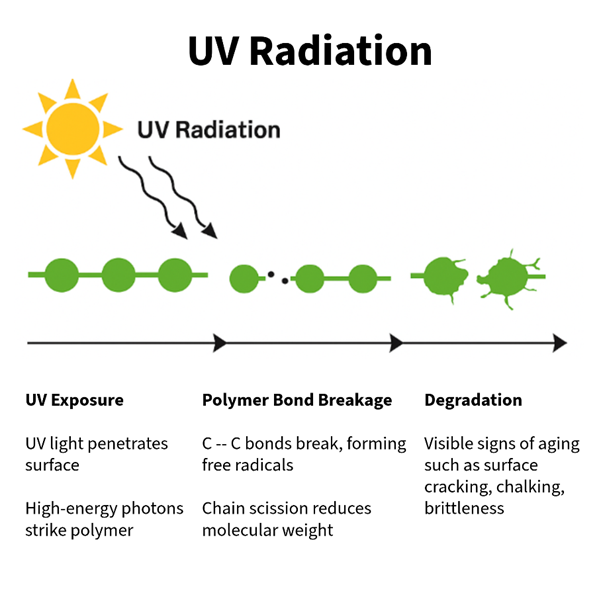

UV Degradation

Ultraviolet (UV) radiation breaks carbon–carbon bonds, such as those found in polyolefins like polyethylene (PE) and ethylene-vinyl acetate (EVA) foams, leading to surface cracking, chalking, and brittleness over time. Materials like neoprene and nitrile also degrade quickly unless stabilized. UV resistance is critical for rooftop, pole-mounted, or outdoor signage applications where prolonged sun exposure can rapidly compromise material.

- Test Methods: UV and Heat Aging (ASTM G154 / D573): Simulates long-term outdoor and thermal exposure.

Image property of Rogers Corporation

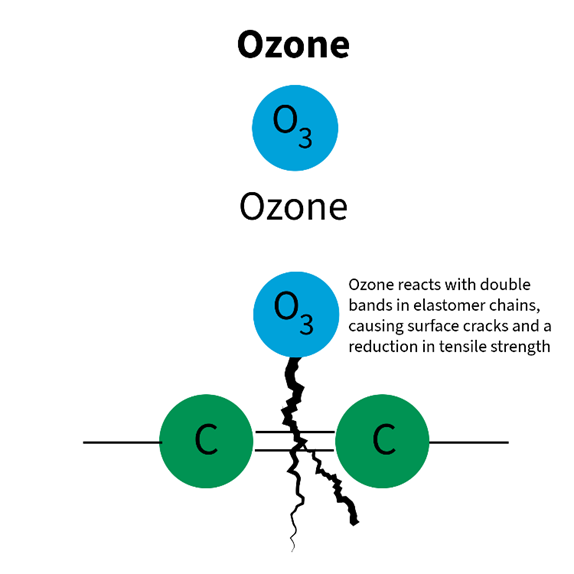

Ozone Attack

Although often overlooked or lumped together with UV degradation, ozone reacts with double bonds in elastomer chains, causing surface cracks and a reduction in tensile strength. This often occurs in industrial environments with high-voltage equipment or electric discharge.

Image property of Rogers Corporation

Let’s recap:

Image property of Rogers Corporation

Comparing Material Families

Different polymer families offer different levels of resistance:

Silicone (e.g., BISCO®):

- Inherently stable due to its Si-O backbone.

- Resistant to UV, ozone, and extreme temperatures.

- Retains elasticity and rebound after years of exposure.

Polyurethane (e.g., PORON®):

- Excellent cushioning and stress relaxation.

- Hydrolysis resistance depends on formulation.

- PORON® formulations are specifically engineered for high hydrolysis resistance, making them suitable for humid or moisture-prone environments.

Neoprene & Nitrile:

- Cost-effective

- Degrade more quickly under UV, heat, and chemical exposure unless stabilized.

Polymer Performance Comparison Table

| Material | UV Resistance | Hydrolysis Resistance | Oxidation Resistance | Ozone Resistance | Long-Term Elasticity |

|---|---|---|---|---|---|

| BISCO® Silicone | ✔️ Excellent | ✔️ Excellent | ✔️ Excellent | ✔️ Excellent | ✔️ Excellent |

| PORON® Polyurethane | ✔️ Very Good | ✔️ Excellent* | ✔️ Good | ✔️ Good | ✔️ Excellent |

| Neoprene/Nitrile | ⚠️ Moderate | ❌ Poor | ⚠️ Low | ⚠️ Moderate | ❌ Poor |

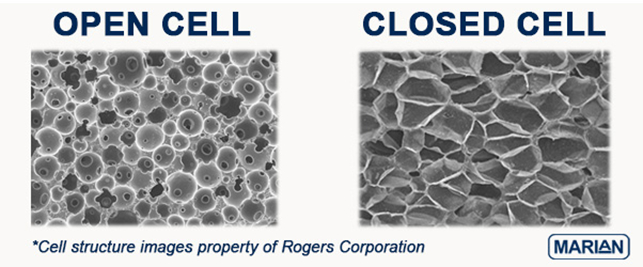

Open Cell vs. Closed Cell Materials

Internal structure matters:

- Open-cell foams (e.g., PORON, BISCO): Allow internal airflow when not compressed, provide better stress relaxation and compression set resistance.

- Closed-cell foams (e.g., neoprene): Resist water ingress but are more prone to internal stress buildup and long-term compression set.

Image property of Marian, Inc.

Real-World Applications

Outdoor LED Signage: Imagine a gasket in an aluminum frame exposed to midday sun and midnight frost. The seal must flex and rebound through thermal expansion cycles while resisting UV damage year-round. Silicone foams excel in these types of applications, as they are UV-resistant.

Automotive Control Modules: Under the hood, temperatures spike and fall rapidly. Ingress from oil, brake fluid, or road spray adds chemical stress. Here, engineers lean on materials that can handle extreme temperatures and fluids. Fluorosilicones excel in these types of applications, as they are stable across a wide temperature range and exhibit excellent chemical resistance.

Telecom Enclosures: Placed high on towers or deep in basements, telecom housings face everything from salt-laden wind to constant humidity. These conditions require foams that resist hydrolysis and maintain seal integrity despite temperature and moisture cycling. Silicone and polyurethane foams are in high demand for these types of applications.

Testing for Longevity

It takes more than a technical data sheet to validate long-term sealing performance. The following test methods simulate years of field conditions to evaluate how materials actually perform over time.

Read our blog on long-term testing reliability for more information.

Severity vs. Time vs. Exposure Matrix

Engineers should match the environmental severity and duration with the expected degradation mode. Here is some general guidance:

| Environment | Severity | Expected Duration | Primary Degradation Type |

|---|---|---|---|

| Outdoor (UV+Heat) | High | 10+ years | UV, Oxidation |

| Automotive Underhood | High | 5–10 years | Heat, Fluids, Hydrolysis |

| Indoor (Mild Humidity) | Low | 5+ years | Stress Relaxation |

| Coastal Telecom | High | 10+ years | Salt Spray, UV, Hydrolysis |

Key Takeaways

Longevity in sealing is not just about initial performance; it's about resisting the full range of chemical and physical stresses encountered over years of use. Understand degradation mechanisms, select the right polymer chemistry, and validate with accelerated tests. This leads to fewer failures, fewer service calls, and better system reliability.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute™

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute™ — a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for the Enclosure Institute™?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an Enclosure Institute Essentials Kit upon completion, recognizing your expertise

The Enclosure Institute™ is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design:

Not ready to enroll yet?

Explore more blogs on enclosure design best practices:

- Everything You Need to Know About Static vs. Dynamic Seals in Enclosures

- What Good Sealing with the Right Partner Looks Like

- Introducing the Enclosure Institute™: Expert Tools to Design Better Enclosures

Your Trusted Partners in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Contact Marian

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Published on Aug 13, 2025

Institute Insight

Institute Insight