Published

by Rogers Corporation

Enclosure Institute, Elastomeric Material Solutions

Welcome back to the Marian and Rogers Enclosure Institute™, your trusted resource for mastering enclosure design and sealing performance.

Sealing performance is not just about the gasket material you choose, it’s about how that material behaves under compression, over time, and within the mechanical constraints of the enclosure design.

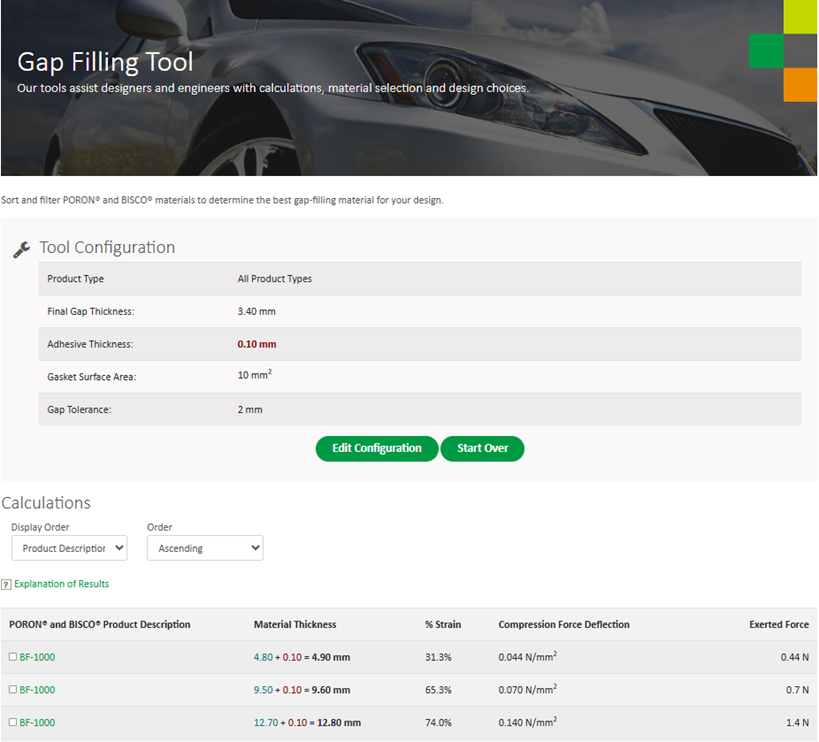

In this blog, we’ll explore the mechanical principles behind reliable gasket design, focusing on gap spacing, compression force deflection (CFD), material compressibility, and gasket width. These factors directly influence your enclosure’s ability to maintain protection against dust, water, and other environmental elements.

Understanding Gap Spacing

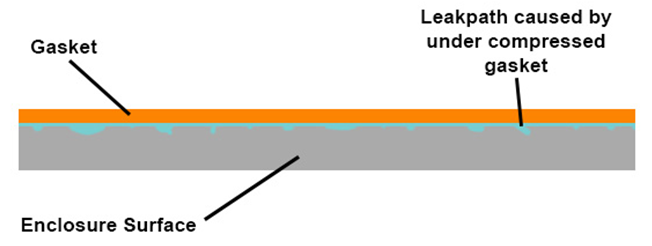

Improper compression ratios are one of the most common reasons enclosure seals fail.

- Too little compression can leave gaps for dust and moisture ingress.

- Too much compression can cause warping of thin enclosures, permanent gasket deformation, or even prevent proper closure.

Image property of Rogers Corporation

Too much compression caused permanent gasket deformation and a leak path.

Image property of Marian, Inc.

The first step in selecting a gasket material is to define the gap that needs to be sealed, including its minimum and maximum thickness.

Best Practices for Gap Spacing:

- Account for tolerance variations across the enclosure’s mating surfaces to ensure a consistent seal on every unit.

- Factor in secondary layers like adhesives, coatings, or films that affect the final compressed thickness.

- Evaluate surface texture — rough or uneven surfaces may require softer, highly conformable materials to ensure full contact.

- For complex shapes or stepped surfaces, softer foams or materials with better recovery properties can adapt to irregularities while maintaining sealing force.

- Select materials slightly thicker than the final gap to achieve an optimal compression range (generally 25–35%).

- Over-compression can cause “bottoming out,” preventing the gasket from rebounding.

- Under-compression may lead to leaks or incomplete sealing.

Image property of Rogers Corporation

Compression Force Deflection (CFD): Matching Pushback Force to Your Enclosure

Once the gap is defined, the next step is selecting a material with the right Compression Force Deflection (CFD).

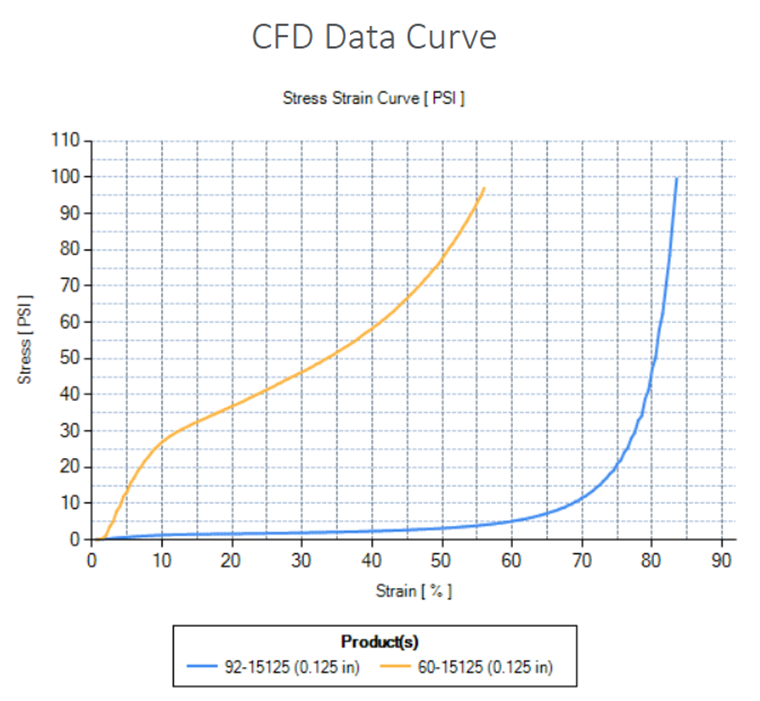

What Is CFD?

CFD measures how much force a gasket pushes back with as it’s compressed. Understanding CFD is essential for ensuring the gasket delivers the right sealing force without overstressing the enclosure.

You can think of it like a stress-strain curve, where force vs. compression is plotted like you see in the image below. The right force balance is critical.

Image property of Rogers Corporation

Here is an example of CFD Data Curve. The material on the left is softer than the material on the right.

Understanding CFD Helps Engineers:

- Determine closure force requirements to compress the gasket to the desired level.

- Match gasket stiffness to enclosure limits, especially in lightweight or plastic housings.

- Balance easy closure and reliable sealing, ensuring low CFD doesn’t underperform and high CFD doesn’t overload latches or panels.

Why CFD Matters for Gasket Selection:

- Soft materials require minimal force but often need greater deflection to achieve an effective seal.

- Firm materials resist compression and provide stability but can create excessive stress on hinges, thin walls, or latch systems.

- Choosing the right pushback force prevents warping, corner lift, or sealing failures during assembly and long-term use.

CFD Examples:

- Soft polyurethane foams like PORON® 92 may require just 2 psi at 25% compression

- Firm polyurethane foams like PORON® 60 may require over 40 psi at 25% compression

If a material’s CFD is too high, especially in latching or snap-fit designs, panels may warp or fail to close properly. If it’s too soft, the gasket may bottom out or fail to create a reliable, long-term seal.

CFD Rule of Thumb:

- <10 psi at 25% compression: Easy closure, ideal for plastic housings.

- 10–30 psi: Balanced sealing and stiffness.

- >30 psi: Heavy-duty enclosures or bolted assemblies.

Balancing Material Compressibility and Seal Performance

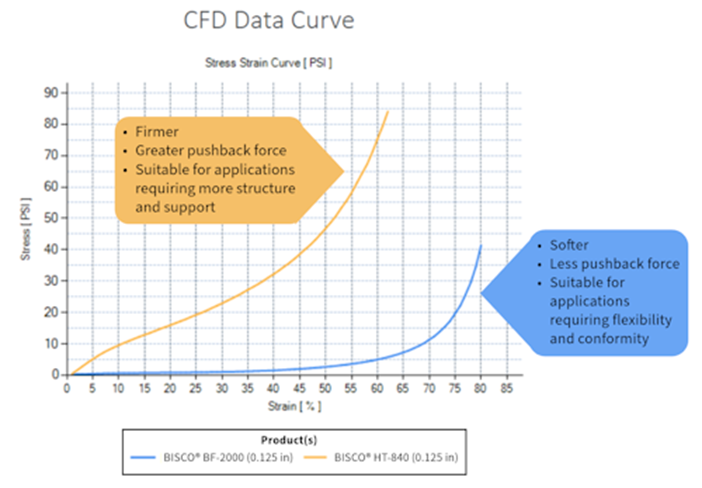

The compressibility of a gasket material directly impacts both its sealing effectiveness and the mechanical stress it applies to an enclosure. However, this relationship is not linear.

Soft vs. Firm Materials

- Soft foams compress with minimal force and easily conform to uneven or rough surfaces, making them ideal for plastic housings or enclosures with surface variations. However, they may require greater deflection to achieve an effective seal and can “bottom out” if over-compressed.

- Firm foams resist compression and provide consistent pushback force over time. They offer better resistance to vibration and long-term stress relaxation but can overload thin walls or latching systems if not carefully matched to the enclosure design.

Image property of Rogers Corporation

Engineering Tips:

- Use low-CFD, soft foams for lightweight plastic housings or snap-fit designs.

- Consider thicker foams to compensate for surface irregularities, tolerance stack-ups, or uneven closure force.

- For high-stress or bolted enclosures, consider using firmer materials to provide durability and reliable sealing.

- Use FEA (Finite Element Analysis) or pressure-sensitive film tests to identify low-compression zones and ensure even gasket loading.

Image property of Rogers Corporation

Gasket Width

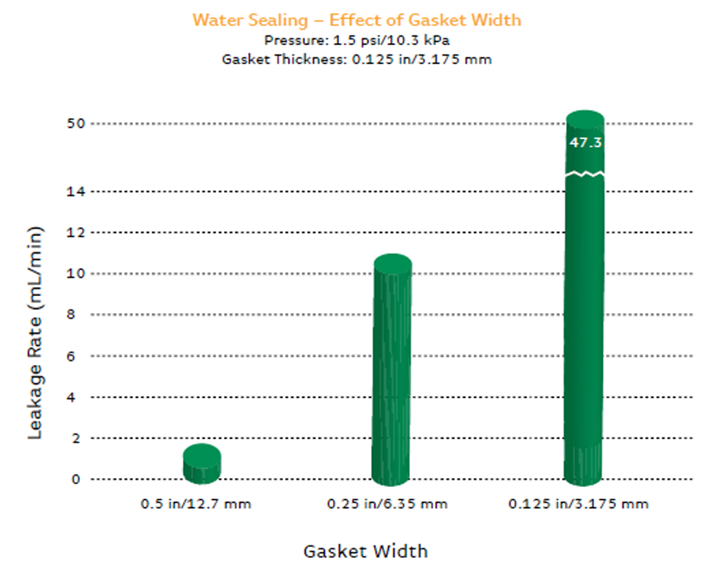

Gasket width doesn’t often get the spotlight, but it still plays a critical role in sealing performance, especially in water sealing applications.

Why Width Matters:

As gasket width increases, the seal line expands, providing more surface area to resist leakage and accommodate irregularities in the mating surfaces. This improves the overall ability of the gasket to block water ingress, even under low compression or modest pressure.

Real-World Data on Width and Leakage

The chart below shows how a silicone performs under 1.5 psi (10.3 kPa) of pressure at varying gasket widths:

| Gasket Width | Leakage Rate (mL/min) |

|---|---|

| 0.5 in (12.7 mm) | 1.5 mL/min |

| 0.25 in (6.35 mm) | 12 mL/min |

| 0.125 in (3.175 mm) | 47.3 mL/min |

Image property of Rogers Corporation

Even with the same thickness (0.125 in / 3.175 mm) and same pressure, the leakage rate increases drastically as the width decreases.

Design Implications

A narrow gasket provides less sealing surface, which:

- Increases the risk of leak paths especially on uneven or warped enclosures.

- Limits tolerance for imperfections or low closure forces.

Key Takeaways

Designing a reliable enclosure seal isn’t just about picking a gasket — it’s about balancing mechanical fit with long-term performance. Engineers should focus on:

- Gap Spacing: Account for tolerance variations, coatings, and surface irregularities to ensure uniform sealing.

- Compression Force Deflection (CFD): Select materials with the right pushback force to avoid over-stressing latches or panels.

- Material Compressibility: Understand how soft vs. firm materials behave under real-world compression and closure forces.

- Gasket Width: Use wider gaskets when possible to improve sealing performance and compensate for imperfect surfaces.

By combining smart mechanical design with materials that offer strong compression set resistance, low stress relaxation, and proven sealing performance, engineers can create enclosure seals that perform reliably for years.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute™

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute™ — a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for the Enclosure Institute™?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an Enclosure Institute Essentials Kit upon completion, recognizing your expertise

The Enclosure Institute™ is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design:

Not ready to enroll yet?

Explore more blogs on enclosure design best practices:

- Expert Tips for Preventing Polymer Degradation in Enclosure Applications

- Everything You Need to Know About Static vs. Dynamic Seals in Enclosures

- What Good Sealing with the Right Partner Looks Like

Your Trusted Partners in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Contact Marian

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Published on Aug 20, 2025

Institute Insight

Institute Insight