Published

by Rogers Corporation

Elastomeric Material Solutions, Enclosure Institute

Welcome back to the Enclosure Institute™, where Marian and Rogers help engineers master enclosure design and precision sealing solutions. From material selection to converting best practices, we provide insights to ensure long-term reliability and performance.

Die-cut foam gaskets may seem simple, but in enclosure design, they’re anything but. Every design choice can impact the durability and manufacturability of the gasket, as well as how easy it is to install.

Factors like construction, material selection, placement, and packaging determine whether a gasket will perform effectively or fail prematurely.

To achieve an optimized sealing solution, engineers must look beyond material selection and consider the entire manufacturing and application process.

Let’s explore eight critical factors that can make or break your die-cut gasket design.

1. Construction: Design for Durability from the Start

The first step in gasket design is defining how the seal will be constructed to meet application requirements. The construction of the gasket determines its performance over time.

Key Considerations

- One-piece gaskets minimize the risk of leak paths and streamline installation, making them ideal for applications where sealing integrity and simplicity are critical.

- Multi-piece gasket designs offer greater manufacturing flexibility and can reduce material waste, but they may introduce challenges related to leak paths and rely heavily on proper installation to maintain sealing performance.

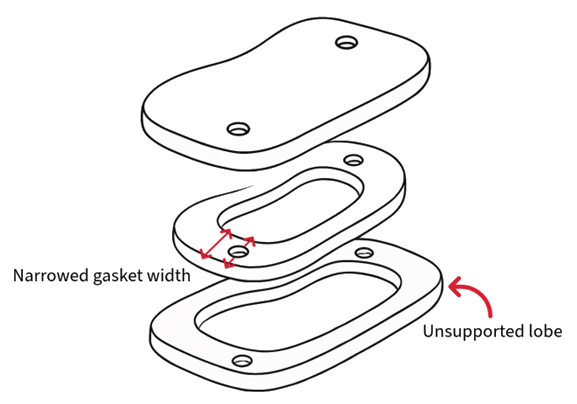

Multipiece gasket design. Image property of Marian Inc

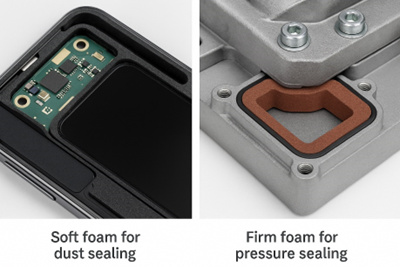

- Match materials to failure modes. Soft, compressible materials work well for dust protection, while durable and flexible foams help prevent liquid ingress. High-density foams or reinforced elastomers are best for pressure-sealing applications.

Image property of Rogers Corp.

- Understanding potential failure modes helps ensure long-term reliability. What does failure look like? Is it dust, water, pressure, electromagnetic interference (EMI)? How little or how much constitutes failure? Water ingress protection may require a material with low water absorption, while pressure loss could indicate the need for a material with high compression set resistance.

2. Optimize Geometry for Better Sealing

Material alone doesn’t guarantee performance. Geometry, layers, and fastening define how your gasket behaves under load.

Design Factors for Optimized Performance

- Fastener type matters. Enclosure fastening methods influence gasket thickness and flexibility. Bolted enclosures require materials that can handle high compression stress, while latched or hinged enclosures need softer, more flexible gaskets.

- Multi-layer gaskets can provide additional functionality, such as EMI shielding, thermal insulation, or vibration damping.

- Proper placement of bolt or fastener cut-outs prevents stress points that can lead to material degradation.

Image property of Rogers Corp

Example: Screw placement narrows the gasket width at these locations, concentrating compression near the fasteners and leaving extended lobes with limited clamping support, potentially leading to seal failure.

- Efficient use of material can reduce costs by repurposing center slugs (cutout material) whenever possible.

3. Match Manufacturing Method to Production Volume

Fabrication method should align with your production needs.

Key Considerations

- Low-volume prototyping benefits from digital knife cutting or water jet cutting, which offer fast turnaround with minimal setup costs.

- High-volume production is best suited for rotary die-cutting or flatbed die-cutting, which offer precision, repeatability, and cost efficiency.

4. Engineer for Easy Assembly and Handling

A great gasket won’t perform as intended if it is difficult to install. Whether applied manually or via automation, designing for usability reduces errors and improves efficiency.

Optimizing for Easy Application

- Pull-tabs and extended liners simplify manual placement and reduce handling errors.

- Stiffeners can improve accuracy when working with thin or flimsy gaskets.

- Selecting the right pressure-sensitive adhesive (PSA) laminate ensures secure adhesion and long-term performance.

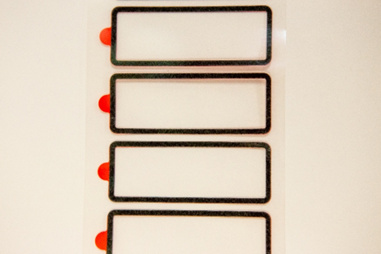

Pull tab on an extended liner. Image property of Marian Inc

5. Use Locating Features to Eliminate Installation Errors

For accurate placement, built-in locating features are often necessary.

Strategies for Precise Alignment

- Locating holes within the gasket or liner helps ensure accurate placement.

- Grooves or cutouts can align with enclosure features for repeatable installation.

- Alignment notches improve consistency and prevent installation errors.

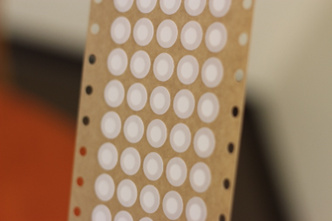

Locating holes on liner. Image property of Marian Inc

6. Select Adhesives for Long-Term Reliability

The right adhesive ensures strong adhesion without compromising performance.

Key Factors for Adhesive Selection

- Surface energy impacts how well adhesives bond to different gasket materials. Some materials, such as silicones, require specialized adhesives.

- Environmental exposure, including temperature extremes, moisture, and chemicals, should be considered when selecting an adhesive.

- Adhesive wet-out, or the ability of the adhesive to fully contact the surface, improves bond strength and durability.

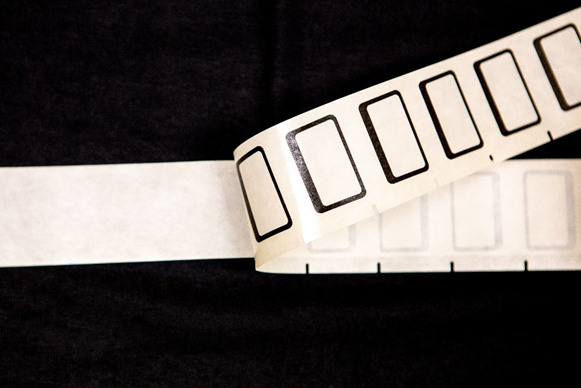

7. Choose Packaging That Protects Parts and Simplifies Use

How die-cut parts are received affects handling, storage, and application efficiency.

Common Packaging and Delivery Methods

- Rolls , sheets, or bulk packaging should be chosen based on storage space and handling needs.

- Kiss -cut liners are ideal for fast, efficient peel-and-stick applications.

- Custom packaging prevents damage during transit and storage.

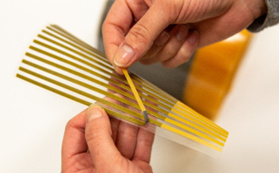

Kiss cut on a roll with pull tabs. Image property of Marian Inc

8. Prevent Damage with Smarter Delivery Options

Packaging plays a crucial role in ensuring quality control and preventing defects.

Best Practices for Protecting Your Parts

- Proper packaging prevents parts from shifting, which helps maintain their integrity.

- Allowing space for pull-tabs prevents premature peeling before application.

- Protective liners help preserve adhesive quality until the part is ready for use.

Image property of Marian Inc

Engineer Gaskets for Long-Term Success

Effective die-cut gasket design goes beyond picking the right foam or elastomer. It’s about engineering for the entire lifecycle, from manufacturability and assembly to environmental durability.

Key Takeaways

- Consider all sealing factors, including material properties, adhesion, and installation.

- Optimize designs for manufacturability to balance cost efficiency and performance.

- Work with an experienced converter to ensure quality, repeatability, and a reliable supply chain.

By applying these best practices, engineers can reduce failure risks, streamline production, and deliver enclosures that perform reliably for years.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute—a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for The Enclosure Institute?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an exclusive swag box upon completion, recognizing your expertise

The Enclosure Institute is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design.

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Not ready to enroll yet? Explore more blogs on enclosure design best practices:

- How To Validate Enclosure Seal Reliability Through 5 Tests

- Expert Tips for Preventing Polymer Degradation in Enclosure Applications

- Everything You Need to Know About Static vs. Dynamic Seals in Enclosures

Your Trusted Partner in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Published on Oct 01, 2025

Institute Insight

Institute Insight