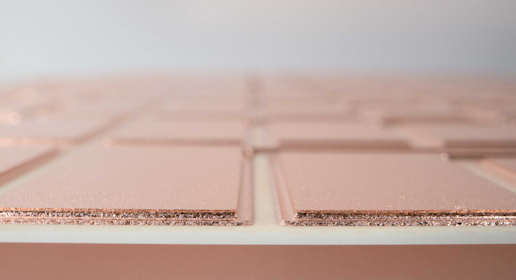

Our curamik Endurance substrates provide enhanced reliability performance compared to material combinations of the same dimensions. This reliability improvement makes the new substrates well suited for high power applications, such as in EV/HEV, vehicle electrification, general industrial, renewable energy and mass transit. curamik Endurance extends the field of applications for DBC.

Features

- Available copper thickness of 0.3 mm

- Ceramic Types available include Al2O3 , HPS (ZTA), AlN

- Thermal conductivities of 24, 26 and 170 W/mK

- Ceramic available in multiple thicknesses according to standard Rogers DBC design rules

Benefits

- Enhanced reliability performance compared to material combinations of the same dimensions

- Suitable for high power applications

- Extraordinary increased lifetime

- Known material and combinations allow for easy implementation

The three curamik Endurance Substrates available include:

curamik Endurance (Al2O3)- Offers thermal conductivity of 24 W/mK @ 20°C

- CTE of 6.8 ppm/K @ 20°C - 300°C

- Available in many thickness combinations

- Alumina (9% ZrO2 doped)

- Offers thermal conductivity of 26 W/mK @ 20°C

- CTE of 7.1 ppm/K @ 20°C - 300°C

- Available in many thickness combinations

- Based on Aluminum Nitride ceramics

- Offers thermal conductivity of 170 W/mK @ 20°C

- CTE of 4.7 ppm/K @ 20°C - 300°C

- Available in many thickness combinations

Downloads

Applications

- Commercial Avionics

- Converters for Wind Turbines & Solar Farms

- Electric Motors

-

eTrucks, eBusses,

Forklifts - EV/HEV Converters, Inverters & Electric Powertrains

- Power Converters & Power Inverters

- Power Transistors

- Propulsion Systems

- Satellite Power Management

- Semiconductor Elements

- Smart Grid: Transmission & Distribution

- Solar Inverters

- Vehicle Electrification

- VFD and UPS