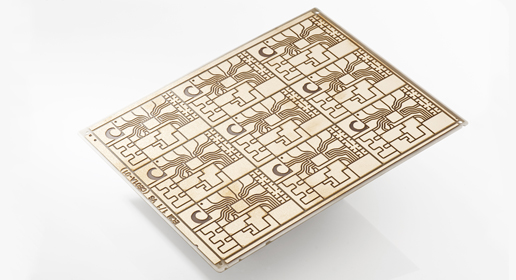

Our curamik Thermal substrates offer the best thermal conductivity in the industry. The substrates' AIN Direct Bond Copper (DBC) provides an adjusted thermal expansion coefficient, which is closer to that of silicon and results in little tension in the solder layer between chip and substrate. Our high-performance curamik Thermal material may be used in very high power density applications, such as train drives, wind turbines and industrial semiconductor modules.

Features

- Based on Aluminum Nitride ceramics

- Offers thermal conductivity of 170 W/mK @ 20°C

- Available in many thickness combinations

- CTE of 4.7 ppm/K @ 20°C - 300°C

Benefits

- Best thermal conductivity in the industry

- Ideal for very high power density applications

- Low CTE and minimal tension in solder layer between chip and substrate

- Provides a lifetime of high performance and reliability

Downloads

Applications

View current applications of this product.